In a recent test series performed in its test lab at Stuttgart, Germany, Coperion together with the technology licensor Lummus Novolen Technology demonstrated the wide range of possible applications for the proven Coperion ZSK twin screw extruder series. Within the scope of tests, various Polypropylene (PP) pellets with extremely low melt viscosities were successfully produced. This so-called meltblown PP forms the raw material for the production of nonwovens, which are mainly used as filter media in medical protective masks.

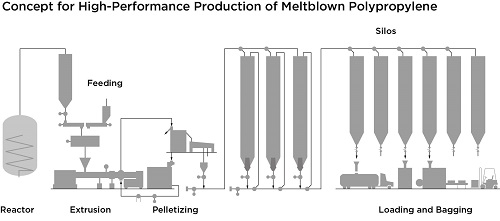

The results obtained from the tests now allow the concept to be easily transferred from laboratory to production scale. Thus, the production of such products on existing and new large-scale extruders, as typically installed in modern PP production sites, becomes possible.

The tests are based on the proven ZSK extruder technology with ZS-EG side devolatilization and a screw design tailored exclusively for Novolen. According to Heiko Hornberger, Head of Team Polyolefins, Process Technology at Coperion, the innovative system concept proves the successful interaction of different technologies. The combination of a new screw concept for optimum dispersion and very good degassing thanks to ZS-EG technology secures first-class product qualities. This is achieved with outstanding process reliability, regardless of throughput rates and melt viscosity. The overall concept of the Coperion system not only ensures the operational flexibility required and necessary by the licensor for the processability of a broad range of PP types, but also significantly extends the possible application window.

For Sebastian Schwarzer, Technology Manager Extrusion at Lummus Novolen Technology, the new concept for the production of meltblown PP represents a milestone as with this process, the licensees of Lummus Novolen Technology are now able to produce these coveted products safely and reliably, without restrictions on the existing product portfolio. Furthermore, the project impressively shows that the interaction between the technological expertise of Lummus Novolen Technology and the innovative system design and competence of Coperion leads to the desired success within shortest development time.

Lummus Novolen Technology makes this new development available to its interested licensees as part of a Process Design Package. The package contains all necessary process parameters and additive recipes. Coperion supplies the machine components for successful implementation.