SABIC Innovative Plastics launched its material solutions designed to help customers around the globe meet today's most pressing demands and challenges. These material solutions enable customers to differentiate their products while increasing productivity and reducing manufacturing costs. International Plastics News - Middle East (IRNE) talked to Mr. Charles Crew, President and Chief Executive Officer (CEO) of SABIC Innovative Plastics on the company's latest material solutions, and how these meet the demand of today's various industries.

IRNE: SABIC Innovative Plastics launched its new materials solutions aimed at diverse industries and applications. What encouraged the company to do so even in the wake of the current global recession?

Crew: The plastics industry is still vibrant despite the crisis and SABIC Innovative Plastics is committed to help the industry grow. For a number of years, we have worked with the best in the industry and made investments towards product and process development. Our commi tment to the plastics industry and our customers is unshakeable even in these hard times and this commitment is clearly evidenced by the aggressive steps we are taking to continue accelerating the development of newer and better sustainable, highperformance, top-quality materials.

"Our commitment to the plastics industry is unshakeable even in these hard times. This is clearly evidenced by the aggressive steps we take to accelerate the development of newer and better sustainable, highperformance, top-quality materials."

- Mr. Charles Crew, President and CEO,

SABIC Innovative Plastics

Our goal is to catapult our materials to greater technological excellence, creating the most innovative products on the market today to help our customers succeed and grow in both existing and new sectors. We have been embarking to develop new material and processes to create new breakthrough end products and these are very much apparent in our co - development efforts with leading OEMs - such as Ford, Samsung, Motorola, and Toyota - which choose SABIC Innovative Plastics as the supplier of choice.

IRNE: Can you name some of the most recent developments in SABIC Innovative Plastics' range of materials solution?

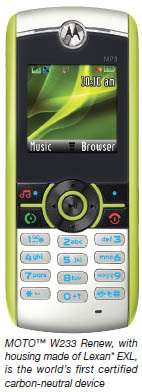

Crew: We have a host of cutting-edge materials aimed at enhancing the products of our customers. One is Motorola's revolutionary new MOTO - W233 Renew mobile phone - the world's first certified carbon - neutral device. This is the result of a long-standing, collaborative relationship between Motorola and SABIC Innovative Plastics, where the new phone uses a customised grade of Lexan* EXL resin made with a significant amount of postconsumer plastic content.

Another important products are the two new bimodal, highdensity polyethylene (HDPE) grades ?SABIC?PE 100 and SABIC PE 80 HD resins - for plastic pipe applications. Long a proven, preferred and widely used technology in Europe, these new resins form part of SABIC's strategy to be a leading global supplier of these materials for high - pressure pipe products used in potable water, gas, oil, mining, and large - scale sewage systems.

We also have our new cutting - edge Ultem* composites, foam and fibre that feature ultra - high flame-smoke - toxicity (FST) performance, extreme toughness, and lighter weight. New LNP* specialty compounds reinforced with natural fibres, as well as a new virtually unbreakable bus driver safety shield using Lexan polycarbonate glazing with Exatec* E900 plasma coating.

We are also proud of being part of the world renowned, awardwinning Hyundai QarmaQ Advanced Technology Demonstration Vehicle 杦hich sports sustainable horizontal body panels made with Xenoy iQ* resin and Valox iQ* resin. The Lincoln MKT concept car that we featured during theNike Magista Obra