A patented new device for multi-manifold dies controls the layer thickness of costly capstock polymers, enabling manufacturers of vinyl siding, glazing, hot tub panels, refrigerator parts, and other sheet products to reduce raw material costs.

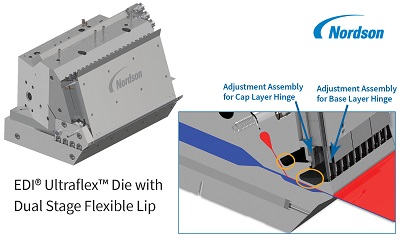

Incorporated in a new EDI® Ultraflex multi-manifold sheet die from Nordson Corporation, the new device consists of a flexible hinge that for the first time makes possible fine-tuning of the capstock layer. Located in the flow channel for the capstock polymer at a point before it combines with the base polymer, the hinge can be adjusted to provide the uniform, streamlined flow necessary for a consistently effective cap layer. At the same time, a conventional flexible lip located downstream can be adjusted to ensure a consistent gauge for the overall two-layer structure.

Schematic of dual stage flexible lip of EDI® Ultraflex sheet die from Nordson Corporation shows the base polymer in blue 0as it moves through the main flow channel, and the capstock polymer in red as it moves through a secondary flow channel before combining with the base polymer. A flexible hinge for fine-tuning the capstock layer is located just before the combining point. The oblique assembly above the die exit controls the thickness profile of the overall coextrusion by adusting the flexible upper lip of the die.

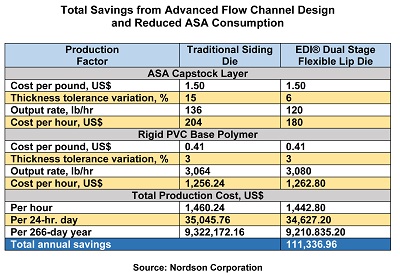

In production runs by a vinyl siding manufacturer, the new dual flex-lip die made possible an 11% reduction in consumption of acrylonitrile-styrene-acrylate (ASA), the polymer widely used in the vinyl siding industry to provide UV protection for the rigid PVC base polymer. This represented an annual saving of US$ 55,669. Because the overall thickness of the siding was unchanged, the amount of ASA saved from being used was replaced by much less expensive rigid PVC. And since the new die necessarily included a flow channel design that was more advanced than that of the old die which it replaced, the total annual savings was actually double the $55,669 amount (see table).

“An EDI Ultraflex sheet die with the new dual-stage flexible lip feature enables vinyl siding manufacturers to produce cladding that provides long-lasting weatherability and good looks, while avoiding the high scrap rates and downtime that can be caused by inconsistencies in the cap layer,” said Patrick Meinen, global product line manager for Nordson’s EDI dies. “In addition, the device eliminates the need to run unnecessarily thick cap layers to compensate for such inconsistencies.”

While currently offering the new technology for vinyl siding applications, Nordson anticipates that it will also provide cost savings in other sheet products that require cap layers for UV protection, gloss, or other special properties. One example is UV layers for transparent polycarbonate sheet used in specialty windows, stadium glazing, and greenhouses. Another is gloss layers for hot tub and refrigerator panels.