Sustainable bio-based plastic films have gained acceptance in a variety of industries as consumer awareness on the impact of plastics on the environment intensifies. For instance, the bio-polylactic acid (PLA) films market was valued at $354 million in 2016, and is expected to surge further to reach $910 million by 2023, growing at a CAGR of 14.5% from 2017 to 2023, according to the estimates by Allied Market Research. The study further noted that the use of bio-based materials as food packaging materials is rising continuously, owing to their advantages over fossil-based plastics. As the packaging industry moves forward in attaining a circular economy, the use of renewable resources in plastics production, biodegradability/compostability and recycling are issues that have become challenges to plastics industry players.

Within this scenario, technologies and production processes now address the concerns of manufacturers who are eager to shift to production of finished products from sustainable or bio-based materials to meet stringent regulations and consumer preference. One such company is Coperion, which has enabled Benin-based blown film manufacturer Asahel Benin Sarl. to produce sustainable, bio-based plastic films in the future by delivering a complete compounding system and sharing the corresponding process engineering expertise.

The Coperion system delivered to Asahel Benin Sarl. included a ZSK 26 Mc18 twin-screw extruder, four highly accurate feeders from Coperion K-Tron, as well as a water bath, an air wipe and a strand pelletiser from Coperion Pelletising Technology.

Before plastic bags and packaging were banned in Benin in July of 2018, this west African manufacturer had made its plastic films using polyethylene (PE). The new law forced the company to completely convert its production. Following a successful test and training phase at Coperion’s Stuttgart test lab, Asahel Benin Sarl will be able to produce biodegradable compounds in its home country with the aid of the ZSK twin screw extruder, and will then further process these on its existing blown film machinery into biodegradable bags and packaging materials.

Importation, production, sale, and possession of petroleum-based plastic bags and packaging has been forbidden in Benin since 2018. Until then, Asahel Benin Sarl. had used both new PE compounds as well as recyclate for manufacturing its films that were then used predominantly in household products and in shopping bags for supermarkets.

Intensive tests at Stuttgart test lab

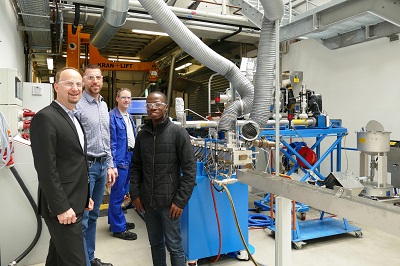

When the new law took effect, the blown film manufacturer had to radically alter its production. Asahel Benin Sarl. turned to the compounding experts at Coperion. From this first contact, a cooperative partnership quickly arose, as did a new corporate strategy thereafter. Asahel Benin Sarl. ordered a laboratory-scale compounding system to develop a biologically degradable compound formulation that could be used in existing blown film manufacturing facilities. The lab-scale system includes a ZSK 26 Mc18 twin screw extruder, four highly accurate powder, pellet, and liquid feeders, as well as a water bath, an air wipe and a strand pelletiser type SP 50. Before the complete system could be delivered to Benin and put into service, it was assembled and tested intensively at Coperion’s Stuttgart location in the test lab.

Sharing process engineering expertise

Throughout the entire project, Asahel Benin Sarl. could fall back on Coperion’s comprehensive, process engineering expertise, for both the mastery of the entire system’s complexity as well of as the seamless interaction of its components, and in particular relating to the twin-screw extruder’s configuration. Formulations with starch content, for example, represent a particular challenge for configuring the twin screws, as the melting zone in the extrusion process must both melt biodegradable polymers and plastify non-meltable starch while adding liquid. Moreover, David Romaric Tinkou, Development Leader of Asahel Benin Sarl., received comprehensive training on the compounding machine’s operation. Thus, began the development of a formulation for the necessary biopolymer.

Flexible set up

Coperion’s experts designed the compounding system for Asahel Benin Sarl. very flexibly in order to enable maximum freedom in developing a suitable formulation. In so doing, the system can allow materials to be added from many different components as well as intensive melt devolatilisation. Following the die head with nozzle comes a water bath for strand cooling, dewatering of the strand surfaces using an air wipe, and a strand pelletiser.

David Romaric Tinkou is very satisfied with how the project went: “It was clear quite quickly that we needed a new business strategy to keep operating our blown film plants here in Benin. I’m very happy that with Coperion, I encountered experienced experts in the field of biodegradable compounds. Coperion delivered not only the necessary technology, but also shared the necessary process engineering expertise with me so that we can manufacture biodegradable compounds ourselves now in Benin.”

Peter von Hoffmann, General Manager Business Unit Engineering Plastics & Special Applications at Coperion, explained: “We’re thrilled that we could support Asahel Benin Sarl. in switching over their production in order to accomplish it more sustainably. Biodegradable compounds from renewable raw materials unite high production-technical demands with environmental sustainability. Particularly for manufacturers of short-lived household, industrial and agricultural products, these compounds represent a long-term, sustainable alternative to petroleum-based raw materials such as PE. Typical areas of application include single-use flatware, trash bags and trash can liners, food packaging, shopping bags, drinking straws, and agricultural films.”

Nike Hypervenom Phantom II FG Low