KRONES AG is advancing its single-source “one-stop-shop” strategy and strengthening its positioning in process technology with its EvoGuard line of high-performance valves. This expansion in the company’s portfolio reflects the company’s commitment to offer products for every point in the production line.

The EvoGuard valve line, which comprises all valve designs for the beverage and dairy industries, includes disk valves, single-seat valves, double-seat valves, double-seal valves, aseptic valves, sampling valves, and control valves. The disk and single-seat types are ideal for simple pipe shut-off tasks, while the double-seal varieties suit highly automated sequences or serve as alternatives for separating hostile media. To provide process and filling technology for aseptic operations, Krones also offers aseptic valves, considered the highest-quality models on the market today for their exceptionally stringent construction.

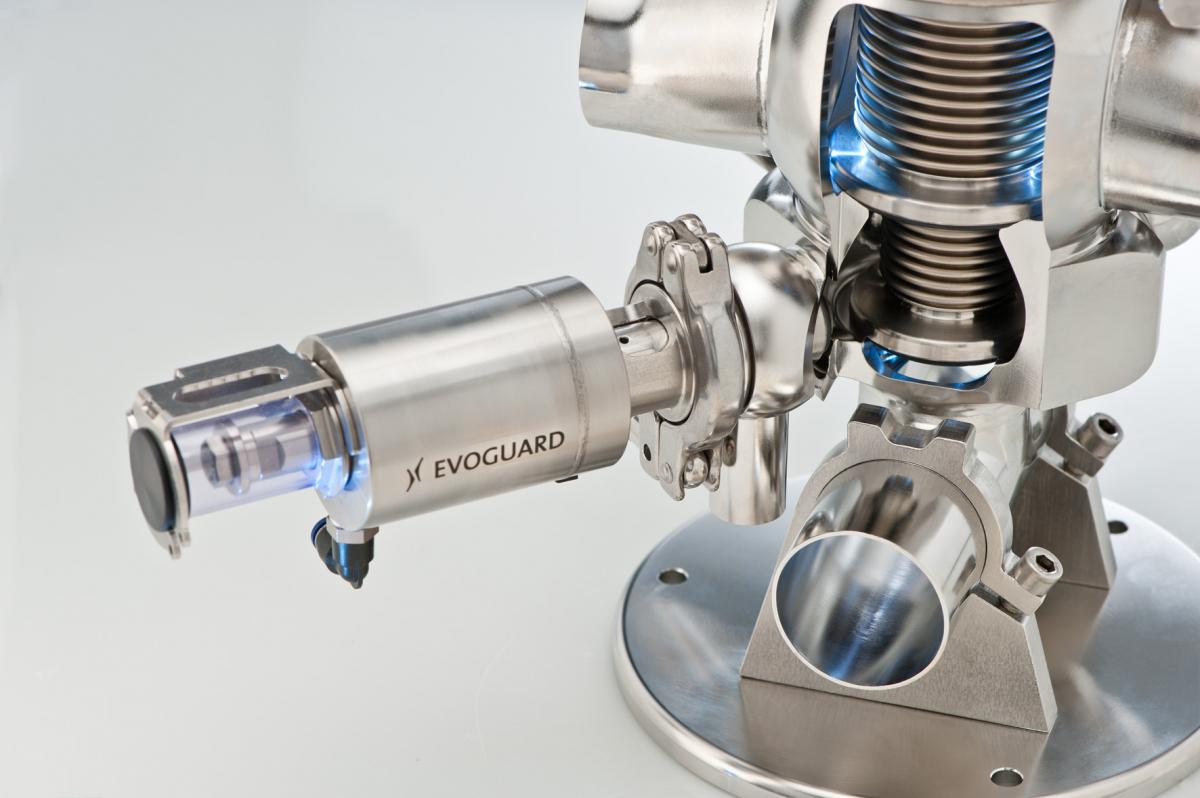

Krones' range of self-designed valves

Aimed at delivering advantages in both daily operation and maintenance routines, the in-house-manufactured valves feature components designed in all commonly used connection variants. The valves adopt nominal diameters customarily used in the food and beverage industries. They use leading-edge material technologies involved in field-proven qualities. The company drew upon decades of experience in plant construction and worked closely with project engineers in designing and producing the valves to ensure they meet the requirements of production operations.

The valves incorporate a high-performance seal. Krones’ designers took into account changes in volume and the stress caused by temperature changes and cleaning routines in the seal design and its installation space. The meaningful design features have been simplified as reflected in the use of standardised model for the disk seal of the double-seat valve and for the axial and radial seals to reduce the risks of mistakes in the event of seal replacement or re-order.

EvoGuard aseptic valves

The EvoGuard valves also boast a welded, maintenance-free actuator designed for long-term use. The actuator for the double-seat valves enables fast cycling of the valve and lowers its compressed-air consumption.

Krones’ family of valves, which proves that there is scope for improvement in every element of a process line, also features extensive and effective measures for boosting occupational safety. All of the valves’ moving parts are protected to prevent accidental interventions. One example is the guard at the link between the valve’s housing and its actuator.

Moreover, the valves adopt a maintenance-friendly design with every sealing point readily accessible and the seals easily replaceable. These contribute to fast, reproducible maintenance workflows that consequently increase overall efficiency. Further, the valves can be easily installed on new machines or during retrofit projects because they use standardised mounting dimensions. The valves’ functional parts can be identified throughout their life span using lot tracking with data matrix codes and serial numbers.

The company’s new aseptic seat valves combine safety and affordability and are designed for classical tasks such as rerouting and shutting off product flows or emptying tanks. The double-seat valves are ideal for separating hostile media in both aseptic and sterile processes, with routings possible even under preprogrammed control. Constructed such that all cross-sectional areas match the nominal diameter involved, the valves eliminate any restrictions on the flow rate and yield actual operational advantages.

Similar to the company’s other EvoGuard valves, the aseptic valves come in modularised versions to enable users to select individual components for particular applications.

Krones AG adopts stringent quality assurance systems to monitor the EvoGuard range of valves. These include batch tracking for all components and certified pressurised parts. In integrating aseptic valves, the company leverages its many years of experience as a line manufacturer to ensure optimum dimensioning and maximum process dependability.

Hombre