PVC fencing profiles

PVC fencing profiles Now that the share of plastic and composite fencing profiles has already increased to approx. 8% of the total fencing demand in the USA, and a double-digit growth rate is expected until 2010, such PVC profiles "with a difference" are also finding more and more customers in Europe and Asia. While in the past such "square pipes" were mainly used to fence in horse paddocks and stables, thanks to their low risk of causing injury to the animals and their easy maintenance, fencing profiles are now becoming more and more popular as railings for verandahs and balconies, and for playing field enclosures in stadiums. In contrast to the more generally known wood profiles, fencing profiles can be produced in an enormous variety of forms, colors and sizes.

Revolutionary machine concept

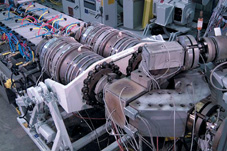

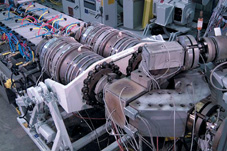

Revolutionary machine concept Battenfeld Extrusionstechnik GmbH, Bad Oeynhausen, Germany supplies the right machinery for their production. The extrusion lines are manufactured by Battenfeld's sister company American Maplan Corporation (AMC) in McPherson, USA, a company with a great wealth of experience in the production of PVC fencing profiles, which draws on this experience for continuous improvement of its machine technology. The German machine manufacturer is responsible for global marketing of this equipment with the exception of Northern and Latin America. AMC offers a unique feed block for twin-strand extrusion of fencing profiles, which requires the use of one extruder plus only one co-extruder. In this feed block, the melt for both the core and the outer layer of the profile is distributed so ingeniously that two homogeneous products can be manufactured from it. The main advantage of using this feed block is a reduction in the capital investment required for twin-strand throughput, since the second co-extruder required for conventional processes is dispensed with. Furthermore, this solution combines a higher output with more modest space requirements. Complete lines with an output of up to 1,350 kg are available for twin-strand extrusion; the maximum performance for single-screw extrusion is 680 kg/h. AMC's wide range of machinery provides all necessary components for each individual processing task. It includes both conical twin-screw extruders for the lower performance range and parallel twin-screw extruders for use in the higher performance bracket, as well as down-stream equipment such as two-chamber vacuum and spray cooling baths, a choice of belt or caterpillar haul-offs and cutting saws or guillotines.

Extensive range of extrusion dies

Extensive range of extrusion dies A special advantage of the American machine manufacturer誷 range are the three different die systems from which its customers can choose: on principle, AMC uses single or double spider pipe heads from the RD or RK series in appropriate sizes for the production of fencing profiles. For instance, a fencing die can consist of a pipe head combined with a standard die/mandrel, with a Teflon 襭reformer?attached to the mandrel which gives the profile its form. The advantage of this concept is its low capital investment cost. Therefore its use is recommended for lines in the lower output bracket and products that do not have to meet high standards of aesthetics. As an alternative, AMC has developed a combination of a conventional pipe head with a rectangular die/mandrel design. The enormous advantage of this variant is that it achieves a perfectly even thickness of the outer layer, even at the corners. Thus higher-quality fencing profiles can be produced with a reduction in material consumption. The use of conventional dry calibration is available as a third alternative, which is of special interest to profile manufacturers who are already using such systems in some of their lines. This solution is recommended for the product

NEW BALANCE PVC fencing profiles Now that the share of plastic and composite fencing profiles has already increased to approx. 8% of the total fencing demand in the USA, and a double-digit growth rate is expected until 2010, such PVC profiles "with a difference" are also finding more and more customers in Europe and Asia. While in the past such "square pipes" were mainly used to fence in horse paddocks and stables, thanks to their low risk of causing injury to the animals and their easy maintenance, fencing profiles are now becoming more and more popular as railings for verandahs and balconies, and for playing field enclosures in stadiums. In contrast to the more generally known wood profiles, fencing profiles can be produced in an enormous variety of forms, colors and sizes.

PVC fencing profiles Now that the share of plastic and composite fencing profiles has already increased to approx. 8% of the total fencing demand in the USA, and a double-digit growth rate is expected until 2010, such PVC profiles "with a difference" are also finding more and more customers in Europe and Asia. While in the past such "square pipes" were mainly used to fence in horse paddocks and stables, thanks to their low risk of causing injury to the animals and their easy maintenance, fencing profiles are now becoming more and more popular as railings for verandahs and balconies, and for playing field enclosures in stadiums. In contrast to the more generally known wood profiles, fencing profiles can be produced in an enormous variety of forms, colors and sizes. Revolutionary machine concept Battenfeld Extrusionstechnik GmbH, Bad Oeynhausen, Germany supplies the right machinery for their production. The extrusion lines are manufactured by Battenfeld's sister company American Maplan Corporation (AMC) in McPherson, USA, a company with a great wealth of experience in the production of PVC fencing profiles, which draws on this experience for continuous improvement of its machine technology. The German machine manufacturer is responsible for global marketing of this equipment with the exception of Northern and Latin America. AMC offers a unique feed block for twin-strand extrusion of fencing profiles, which requires the use of one extruder plus only one co-extruder. In this feed block, the melt for both the core and the outer layer of the profile is distributed so ingeniously that two homogeneous products can be manufactured from it. The main advantage of using this feed block is a reduction in the capital investment required for twin-strand throughput, since the second co-extruder required for conventional processes is dispensed with. Furthermore, this solution combines a higher output with more modest space requirements. Complete lines with an output of up to 1,350 kg are available for twin-strand extrusion; the maximum performance for single-screw extrusion is 680 kg/h. AMC's wide range of machinery provides all necessary components for each individual processing task. It includes both conical twin-screw extruders for the lower performance range and parallel twin-screw extruders for use in the higher performance bracket, as well as down-stream equipment such as two-chamber vacuum and spray cooling baths, a choice of belt or caterpillar haul-offs and cutting saws or guillotines.

Revolutionary machine concept Battenfeld Extrusionstechnik GmbH, Bad Oeynhausen, Germany supplies the right machinery for their production. The extrusion lines are manufactured by Battenfeld's sister company American Maplan Corporation (AMC) in McPherson, USA, a company with a great wealth of experience in the production of PVC fencing profiles, which draws on this experience for continuous improvement of its machine technology. The German machine manufacturer is responsible for global marketing of this equipment with the exception of Northern and Latin America. AMC offers a unique feed block for twin-strand extrusion of fencing profiles, which requires the use of one extruder plus only one co-extruder. In this feed block, the melt for both the core and the outer layer of the profile is distributed so ingeniously that two homogeneous products can be manufactured from it. The main advantage of using this feed block is a reduction in the capital investment required for twin-strand throughput, since the second co-extruder required for conventional processes is dispensed with. Furthermore, this solution combines a higher output with more modest space requirements. Complete lines with an output of up to 1,350 kg are available for twin-strand extrusion; the maximum performance for single-screw extrusion is 680 kg/h. AMC's wide range of machinery provides all necessary components for each individual processing task. It includes both conical twin-screw extruders for the lower performance range and parallel twin-screw extruders for use in the higher performance bracket, as well as down-stream equipment such as two-chamber vacuum and spray cooling baths, a choice of belt or caterpillar haul-offs and cutting saws or guillotines.  Extensive range of extrusion dies A special advantage of the American machine manufacturer誷 range are the three different die systems from which its customers can choose: on principle, AMC uses single or double spider pipe heads from the RD or RK series in appropriate sizes for the production of fencing profiles. For instance, a fencing die can consist of a pipe head combined with a standard die/mandrel, with a Teflon 襭reformer?attached to the mandrel which gives the profile its form. The advantage of this concept is its low capital investment cost. Therefore its use is recommended for lines in the lower output bracket and products that do not have to meet high standards of aesthetics. As an alternative, AMC has developed a combination of a conventional pipe head with a rectangular die/mandrel design. The enormous advantage of this variant is that it achieves a perfectly even thickness of the outer layer, even at the corners. Thus higher-quality fencing profiles can be produced with a reduction in material consumption. The use of conventional dry calibration is available as a third alternative, which is of special interest to profile manufacturers who are already using such systems in some of their lines. This solution is recommended for the productNEW BALANCE

Extensive range of extrusion dies A special advantage of the American machine manufacturer誷 range are the three different die systems from which its customers can choose: on principle, AMC uses single or double spider pipe heads from the RD or RK series in appropriate sizes for the production of fencing profiles. For instance, a fencing die can consist of a pipe head combined with a standard die/mandrel, with a Teflon 襭reformer?attached to the mandrel which gives the profile its form. The advantage of this concept is its low capital investment cost. Therefore its use is recommended for lines in the lower output bracket and products that do not have to meet high standards of aesthetics. As an alternative, AMC has developed a combination of a conventional pipe head with a rectangular die/mandrel design. The enormous advantage of this variant is that it achieves a perfectly even thickness of the outer layer, even at the corners. Thus higher-quality fencing profiles can be produced with a reduction in material consumption. The use of conventional dry calibration is available as a third alternative, which is of special interest to profile manufacturers who are already using such systems in some of their lines. This solution is recommended for the productNEW BALANCE