GEA’s vertical SmartPacker CX400 D-Zip for pre-packaged food products will be launched in November. According to the company, this machine for retail and foodservice combines fast, high-quality operation with maximum flexibility and uptime. It can produce premium quality D-ZIP bags, as well as more than 10 different bag styles for a wide variety of applications such as candy, nuts, frozen fruits and grated cheese.

While the company’s SmartPacker has been on the market for more than sixty years, the CX400 D-Zip meets the current needs of processors and consumers. The vertical packaging machine has an output of up to 100 D-Zip bags/minute. Users can enjoy 98% uptime and highly accurate operation from a machine that carries the smallest footprint of any other comparable machine in the industry.

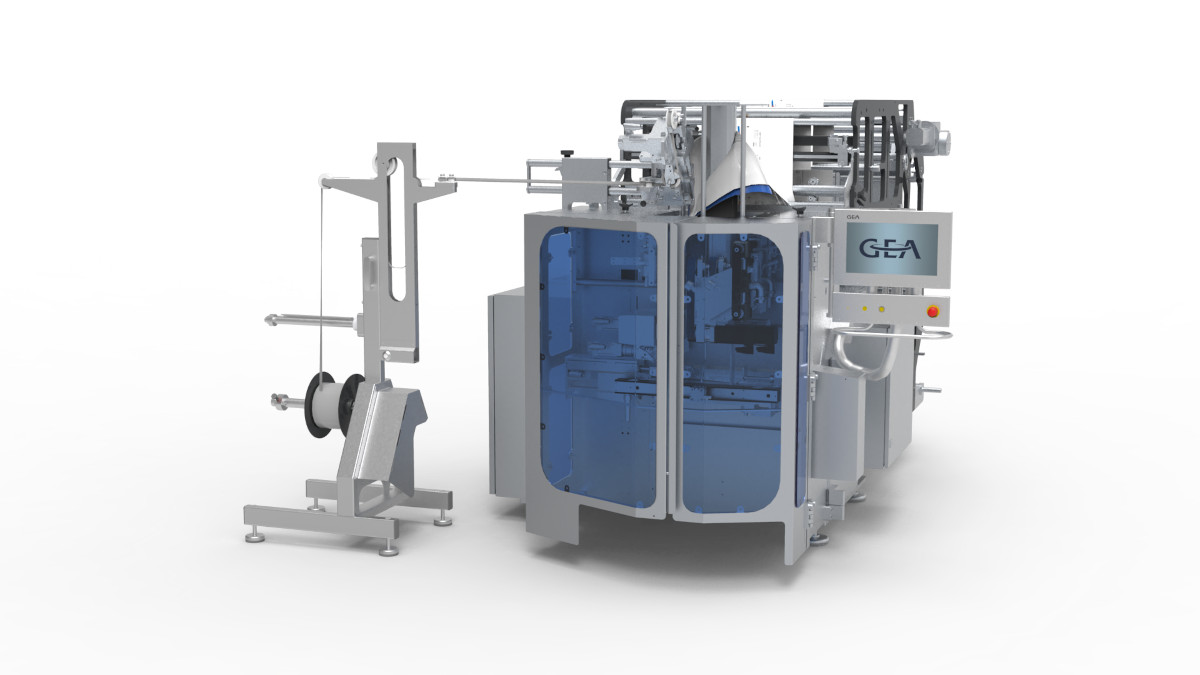

The new GEA SmartPacker CX400 D-Zip produces all popular bag types at high capacity, including zippered stand-up pouches. (Photo GEA)

GEA engineers developed the CX400 D-Zip with industry trends in mind: more flexibility in bag-styles is required, as seen in the increasing demand for stand-up pouches; a need to reduce maintenance costs and downtime; combining the high-quality of the pouches made on conventional horizontal machines with the advantages of a SmartPacker; as well as the need for increased sustainability in manufacturing.

Ease of use is another key feature. The machine creates all existing bag styles; has a changeover time of under 45 minutes – without the use of special tools – and features front discharge. The premium quality D-Zip bag has smooth and sharp cross seals, an elegant and slim design, wrinkle-free seals with high density and air/gas-tight sealing.

The GEA SmartPacker CX400 D-Zip packaging machine combines the popular high-quality pouches made on conventional horizontal machines with the advantages of a SmartPacker. (Photo GEA)

Flexible corner seal unit

The SmartPacker CX400 D-Zip features GEA’s new corner seal unit, which simplifies set-up and improves overall quality. The corner seal unit introduces greater flexibility into the SmartPacker, as it is capable of varying in seal width and, depending on needs, can be configured for two or four seals. Like the GEA SmartPacker CX400 D-Zip, it has a compact design and does not require specialist tooling when changing formats. GEA engineers have also included a superior accessibility to areas where heavy wear can be expected, including sealing and folding to reduce maintenance time.

Smart design cuts amount of plastic required

The GEA SmartPacker CX400 D-Zip design reduces the amount of plastic required for the zipper by approximately 15% by eliminating the zipper-material in the cross seal. Additional plastic waste is avoided given no punching is required in making the zipper.

“The SmartPacker CX400 D-Zip is future-ready,” says Martijn van de Mortel, Product Manager Vertical Packaging at GEA. “Whether the need is for high quality, more capacity, greater flexibility, a small footprint, low maintenance or a combination of all of these, the SmartPacker CX400 D-Zip answers the call. It’s capable of producing all common bag types on a single machine without compromising any expectations.”