Low cost automation less than the price of the established automation suppliers for just a few thousand euro – this is exactly what many users want. But making wishes a reality is often a difficult task: What products go together? How good is the solution? Who can support me? At the Hannover Messe 2019, the motion plastics specialist igus is presenting two new approaches: A new 4 to 5-axis "rohbot" (h for half-finished) made of plastic and a model of the online marketplace for suppliers and users.

The reasons for using low cost automation are as varied as the applications. Mechanical engineering companies and robot manufacturers want to build their own products with a few cost-effective parts; production plants with their own automation systems choose "half-finished" robots (as “rawbots”) and adapt the control system and components to their standards. Small companies, in contrast, want to use ready-made systems easily and, above all, very cost-effectively. igus takes these different requirements into account and presents new hardware components in the form of the "rohbot" concept as well as a digital marketplace model for the the first easy steps in the world of cost-effective automation.

Articulated arms with new design

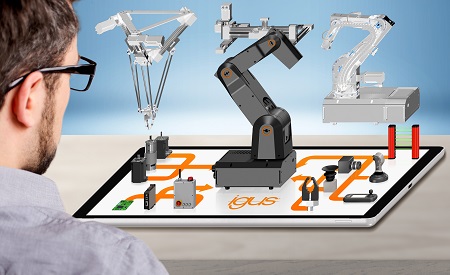

The basic "rohbot" that igus is offering for this growing market segment is the underlying electromechanical framework in the form of a robolink 4- or 5-axis articulated arm, a delta robot or a Cartesian robot. Thanks to a modular kit principle, tailor-made lubrication-free and maintenance-free robotic systems can be assembled. Motors, gears, power electronics, control system, GUI – Everything can be freely chosen. At the Hannover Messe 2019, igus is presenting the latest range of its articulated arm robot. The compact and lightweight articulated arms make comprehensive use of the advantages offered by igus motion plastics: light, lubrication-free and maintenance-free, durable and more cost-effective in production. As a result, small, configurable quantities can be created as well as large quantities for mechanical engineering companies and robot manufacturers. The clearance of the new arms has been further reduced as a result of the plastic design, an innovation that enables greater precision of the robolink. Thanks to integrated cable conduits, the cables are routed inside the latest housed version. This reduces the installation space needed and prepares the articulated arms for general use as well as in the area of human-robot collaboration (HRC). The new DC articulated arm can be configured individually and, depending on the type of application, can be equipped with grippers, cameras or sensors of a wide range of manufacturers. A new kind of online platform, the model of which igus is presenting together with co-exhibitors in Hall 17, can be helpful in this regard.

From the individual component to the complete automation solution

The digital marketplace is intended to help the customer to find and integrate exactly the right low-cost automation solution that he needs for his application. Irrespective of whether he wants to build something himself with individual components or is looking for a cost-effective ready-made solution. Customers without any robotics know-how who want to automate manual tasks easily, as well as professionals who put together their own specific solution profit from this. For suppliers, the marketplace model offers easy access to a rapidly growing market segment. "We invite component producers, robot manufacturers, integrators and end customers to discuss the possibilities of a marketplace with us in Hall 17", says Stefan Niermann, head of the newly created Low Cost Automation business unit at igus. At the same time, visitors will be able to experience a real marketplace on the igus trade fair stand at first hand. "Together with technology partners, we will be showing visitors the possibilities that low cost automation has for them today – and they are enormous."

igus GmbH is a globally leading manufacturer of energy chain systems and polymer plain bearings. The Cologne-based family business has offices in 35 countries and employs 3.800 people around the world. In 2017, igus generated a turnover of 690 million euros with motion plastics, plastic components for moving applications. igus operates the largest test laboratories and factories in its sector to offer customers quick turnaround times on innovative products and solutions tailored to their needs.