After shifting of India’s flagship plastic industry show Plastindia to Gandhinagar, capital of Gujarat, there is always an undercurrent to have a new show that focuses on machinery in the Northern part of India. The ‘Indiaplast’ show has evolved in the past few years, and now emerged as one of the prominent events in India’s plastic industry.

The exhibition is organised jointly by the New Delhi based apex body of Indian plastics machinery manufacturers, the PMMAI (Plastics Machinery Manufacturers Association of India) and Triune Exhibitors, and showcased the latest technology in plastics, packaging, printing, mould making & recycling from February 28 to March 4, 2019 at the India Expo Centre, Greater Noida, Delhi NCR (National Capital Region).

India Expo Center & Mart is now regarded as country’s best trade fair venue. It is also the first integrated international exhibition and convention centre with a unique mix of latest infrastructure and facilities. Greater Noida Industrial Area is located at the intersection of the Western and Eastern Dedicated Freight Corridors and is also the gateway to the Delhi-Mumbai Industrial Corridor (DMIC). It lies within the National Capital Region of India’s capital – New Delhi and is adjacent to Noida, one of the largest industrial townships in Asia.

Interestingly, the first edition of Indiaplast 2019 is also the last edition of the show, as the show will have a different name in its next edition. Sunil Jain, President of Rajoo Engineers Ltd & Treasurer of PMMAI, announced during the inaugural session that the next PMMAI exhibition ‘Indiaplast’ is renamed ‘Plastfocus 2022’ and held at the same venue India Expo Mart Noida. To be held every three years, the exhibition will have some similarities with the flagship event ‘Plastindia’ in Gandhinagar in Gujarat also held once in three years.

Quality exhibitions viewed by thousands of visitors

The show was a complete sold-out with almost every nook and corner of the venue occupied by exhibitors. In fact, the exhibition floor featured live demonstrations of machines - many for the first time ever – as 945 exhibitors from over 18 countries were showcased either as individual exhibitor or under country pavilions, recycling pavilion, innovation pavilion and more, which created significant value added for every discerning visitor, according to Cyril Periera, Managing Director of Triune Exhibitors. Mr. Periera added, “The focus of Indiaplast is to create space and opportunity for each exhibitor to showcase world-class, yet affordable solutions for the plastics industry.”

Underlining the importance of technology, Mahendra N. Patel, Chairman, PMMAI stated during the show opening, “There is a perception that Indian machinery lacks in latest technology advances. Indiaplast showcased technology from Indian manufacturers, which is at par with the best in the world. In fact, almost all PMMAI members are routinely exporting machines around the world including first world countries. Processors who desire to export quality products will surely find latest technology machinery suppliers right here.” Machinery exports of over 300+ members of PMMAI reached over INR 20 billion in 2018.

The show highlights the evolving trends in the Indian plastics industry, which focuses on localisation of machinery manufacturing under the government’s “Make-in-India” drive besides a clear trend towards all-electric injection moulding machines.

For instance, India’s major injection moulding press maker Windsor Machines has introduced all-electric range from Korean firm LS Mtron as part of its joint venture agreement. “With demand for all-electric injection moulding presses firming-up and we have no electric range in our portfolio, the tie-up with Korean firm LS Mtron will fill the electric machine gap in our range,” informed T S Rajan, CEO, Windsor Machines.

The exhibition responded to the fast-changing dynamics in the Indian plastic industry, which is forced to take steps to control the rising plastic waste in the country. The vision to create a plastics economy where products are 100% recyclable and leave minimal wastage was apparent in the exhibition. India’s largest packaging film producer Uflex showcased recycling line for the first time. From the array of revolutionary products on display from Uflex set another milestone with its live demonstration of its recycling machine at the Green Pavilion of PMMAI.

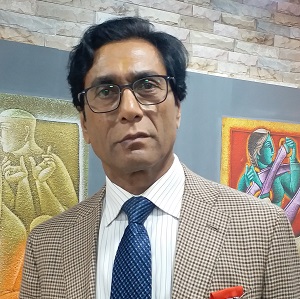

Mr. Ashok Chaturvedi, Chairman, Uflex Limited

Uflex is also confident of demand for flexible packaging growing further in the coming years. Ashok Chaturvedi, Chairman, Uflex Limited commented on the industry outlook, “When there is a complete solution for the waste plastics, the demand is bound to grow. This particular solution of recyclability will encourage people to use more plastic-based materials. I also think that this is the cheapest and best possible option available in the market for packaging edible items. This will definitely help increase the demand of flexible packaging.”

Uflex displayed how Multi-layer Packaging (MLP) Waste is recycled into pellets through a fairly simple method at the recycling pavilion. Mr. Chaturvedi stated that, “People are of the perception that plastics are not recyclable. It is for the visitors to witness themselves the possibilities of recycling plastics and converting it into something useful at the Green Pavilion. The best part is that this machine does not emit any toxins.” He also stated that after recycling plastic, the material can be reused in 10,000 different ways like paver tiles, roads, road dividers, signboards, cupboard, outdoor furniture and many more. Mr. Chaturvedi also praised the show, “Indiaplast 2019 has provided Uflex a good platform to showcase its solution for recycling plastics.”

Mr. Amit Pendse, Managing Director, Electronica Plastic Machines

Another exhibitor, Electronica Plastic Machines, believed the show emerged as game changer for the Indian plastic industry. “Indiaplast has not only been designed for plastic machinery manufacturers only but for the entire plastic fraternity. Moreover, exhibiting at the show was a satisfying experience considering the footfall of business visitors. Almost 75,000 business visitors already visited the show in the first three days,” said Amit Pendse, Managing Director, Electronica Plastic Machines.

Interestingly the 25-year-old company launched a couple of new products at Indiaplast. “We have unveiled ‘Ventura’ with CE mark, that opens up new horizons in the European market and hydraulic Ram Type machine ‘Hylock 350’ for application in houseware, appliances, household furniture & containers,” according to Mr. Pendse.

India is a fast-emerging market for used plastic machinery. Incorporated in the year 1993, Noida-based Advance Plastic Machinery is a major importer and supplier of a predominant grouping of imported used plastic injection moulding machines, tool room machines, retrofitting PLC controllers, linear scales, temperature controllers, grinder machines, hopper loaders, dryer etc. “We import machinery from Japan only, recondition them and sell them in the Indian market. Japanese machinery is good but also expensive and we make them available in India at a reasonable cost,” informed Sahil Kumar, Director, Advance Plastic Machinery.

The company deals in world’s best brands like JSW, Sumitomo, NISSEI, Mitsubishi, Kawaguchi, and Toshiba. “We are growing 25% annually which further indicates growing market for used machines in the Indian plastic industry. We have clientele of over 1,200 companies.” Advance Plastic Machinery plans to enter into manufacturing of injection moulding machines in the future and seems overly satisfied with the participation at the show. “This show provided us the right platform to grow, the organisers have done wonderful job and bringing quality business visitors made it a great experience,” he stressed.