Demand for lighter-weight rubber moulded products is growing in many industrial fields such as automobiles and transportation vehicles like airplanes, as well as in other diverse fields such as wearable devices. With the development of lighter weight products, further expansion of silicone rubber applications are expected.

Shin-Etsu Chemical Co., Ltd. has developed a low-density type of moulding silicone rubber that realises lighter-weight rubber moulded products. Tokyo-based Shin-Etsu is the first company in the industry to have developed this type of moulding silicone rubber using Liquid Injection Moulding System (LIMS) materials. Whereas in order to make lighter-weight silicone rubber, a foaming agent was added to millable-type silicone rubber and moulded into a sponge-like form. However, Shin-Etsu’s product does not require the adding of a foaming agent. Furthermore, because it can be moulded using advanced LIMS, it can meet the demand from moulding-makers for superior quality and improvements in productivity.

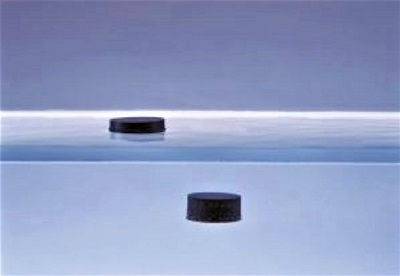

Shin-Etsu offers low-density type of moulding

silicone rubber for lighter moulded products.

This new product is available in two types. The low-density/high strength type realises about a 20-30% reduction in weight as compared to conventional silicone rubber moulding products. The very low-density type realises about a 50-60% reduction in weight as against conventional silicone rubber moulding products. Both can make continuous automatic moulding possible through the use of an injection moulding machine, and therefore can efficiently produce high-quality rubber moulded products, resulting in improvements in productivity as well as energy savings.

Silicone rubber combines many superior characteristics such as excellent heat resistance, cold resistance, weatherability and stable electrical insulation properties, all of which are not found in ordinary organic rubber. For this reason, it is used in a wide range of applications such as in automobiles, electric-electronics equipment, OA equipment, home appliances and products for daily use.

Thermal interface materials for vehicles

Another recent development from Shin-Etsu is its innovative silicone thermal interface materials for applications in electric vehicles (EV) and hybrid electric vehicles (HEV). With the electrification of automobiles, the demand for heat dissipation measures for lithium-ion batteries and for various other electronic control systems are increasingly becoming more sophisticated and diversified. With the accelerating worldwide growth in vehicle electrification, the amount of thermal interface materials in automotive parts has increased and their applications are expanding.

Silicone thermal interface materials for applications

n EVs and HEVs

In response to this changing market environment, Shin-Etsu Chemical has developed two kinds of new products with unique characteristics. The TC-PEN Series features a distinctly reduced density, soft thermal interface pad that can meet the demand for a high level for EV and HEV applications; while the TC-SET Series features a high thermal interface soft pad with very low compression set characteristics.

Due to its significantly low density level that was achieved, the TC-PEN Series realised about a 15% lighter weight when compared to conventional products, while also maintaining the same level of thermal conductivity characteristics and workability of conventional products. As a result, this new product is lighter in weight and is superior in flexibility of handling, making it suitable for applications as a heat dissipation element in electronic devices with non-flat surfaces and in large area parts such as lithium-ion batteries.

The TC-SET Series achieved the maintenance of both the flexibility by low hardness and low compression set characteristics that were very difficult to achieve up until now in this technical field. As a result, this product is suitable for achieving heat dissipation for various electronic devices used in tough automotive applications that require long-term durability against vibrations and low compression set characteristics.

In addition to its innovative silicone soft pads, Shin-Etsu has an extensive portfolio of other silicone thermal interface materials. It offers various types of thermally conductive products such as silicone rubber sheets, greases (oil compounds), gap fillers and liquid rubbers (adhesives, and potting agents).

Along with the development of these new products, Shin-Etsu is moving forward in meeting customers’ more sophisticated requests regarding such areas as technical support with thermal analysis technologies, and has started manufacturing and processing at the International Standard for Automotive Quality Management Systems (IATF)16949:2016 approved plants. The company also has a silicone rubber moulding technical centre where it carries out demonstrations of moulding using its products.