Engineering polymers are known for their design flexibility and, when re-inforced, for their excellent mechanical properties, although these fail to rival those of metals in some respects. The idea of combining the low density of polymers with the high strength and stiffness of metals holds out the promise of attractive development opportunities. Such plastic/metal hybrids are established today, but fail to fully tap the potential of metals, which serve as the internal structure for the molded part - and thus are positioned in the region of the neutral fiber.

Engineering polymers are known for their design flexibility and, when re-inforced, for their excellent mechanical properties, although these fail to rival those of metals in some respects. The idea of combining the low density of polymers with the high strength and stiffness of metals holds out the promise of attractive development opportunities. Such plastic/metal hybrids are established today, but fail to fully tap the potential of metals, which serve as the internal structure for the molded part - and thus are positioned in the region of the neutral fiber. Nanometals on plastic parts

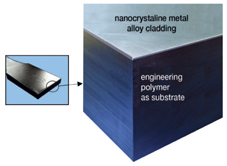

A more compelling solution is to clad a molded component in a high-strength metallic outer skin. Nanocrystalline metals, or nanometals, are ideal because their grain size is orders of magnitude lower than that of conventional metals, and the yield point increases with decrease in grain size. Declining size is also accompanied by improvements in other material properties, such as strength, hardness, abrasion resistance and coefficient of friction.Nanometal/polymer hybrids?myriad applications present themselves in automotive construction, consumer electronics, sporting goods and other areas.

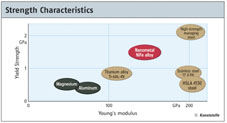

This is precisely the route chosen by DuPont Engineering Polymers together with Morph Technologies Inc. and Integran Technologies Inc., from Canada, and with PowerMetal Technologies, from the USA, with its launch of the Meta-Fuse nanometal/polymer hybrid technology. The patented method yields nanocrystalline metals, whose average grain size of about 20 nm is around 1,000 times smaller than that of conventional metals and whose strength is 2 to 3 times higher than that of typical steel and nickel-chromium coatings. As a result, relatively thin coatings of typically 25 to 200mm thickness are enough to produce high-strength metal/polymer hybrids. The results are extremely lightweight components, which are comparable in stiffness and strength to those of magnesium or aluminum, yet which preserve the design flexibility and the low weight of the engineering plastics.

This is precisely the route chosen by DuPont Engineering Polymers together with Morph Technologies Inc. and Integran Technologies Inc., from Canada, and with PowerMetal Technologies, from the USA, with its launch of the Meta-Fuse nanometal/polymer hybrid technology. The patented method yields nanocrystalline metals, whose average grain size of about 20 nm is around 1,000 times smaller than that of conventional metals and whose strength is 2 to 3 times higher than that of typical steel and nickel-chromium coatings. As a result, relatively thin coatings of typically 25 to 200mm thickness are enough to produce high-strength metal/polymer hybrids. The results are extremely lightweight components, which are comparable in stiffness and strength to those of magnesium or aluminum, yet which preserve the design flexibility and the low weight of the engineering plastics. Optimizing materials use

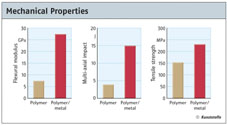

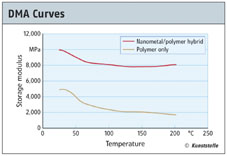

An advantage of the nanometal/polymer hybrids is that the metal can be placed in the optimum location to maximize stiffness. For bending and torsional loads, this is the component's outermost edges, furthest removed from the neutral fiber and where maximum tensile and compressive stress occur. It is where the outstanding mechanical proper ties of nanometals come to the fore. The flexural stiffness of a component increases because it is the product of the modulus and the moment of inertia. The latter is increased exponentially by moving the coating away from the neutral fiber. Similar considerations also apply to the torsional stiffness and strength. The properties of MetaFuse hybrid systems have been characterized in a number of experiments on different engineering polymer substrates. The figure shows typical results from tests on molded ISO tensile bars made from Zytel PA66 containing 25% by weight glass fiber reinforcement, and then clad with 100mm of nanocrystalline nickel-iron alloy showed that the flexural modulus and impact strength were two to four times those of the unclad polymer. The actual values are heavily dependent on sample geometry, metal thickness and substrate. Thus, the tensile strength is directly proportional to the amount of metal used. Based on the results of tests on cantilevered beams of nanometal/polymer hybrids, in which the thickness of the substrate (Zytel HTN PPA from DuPont) varies, the positioning of the metal layer allows further optimizations to be tailored.

Air Jordan

Air Jordan