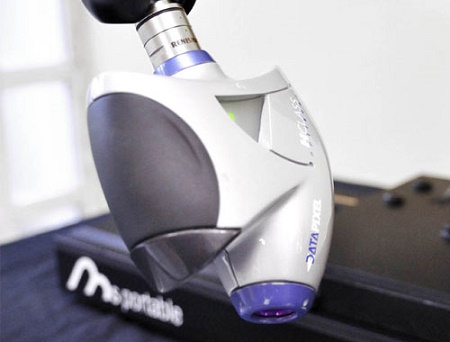

The need to optimize the process is important for companies and after much effort, quality control is now part of the process. Therefore, optical sensors and new data processing systems have been incorporated that have contributed to shorten the time dedicated to quality management. The incorporation of these optical sensors such as Optiscan and new software solutions with M3 Software has facilitated the natural process of accepting the role of metrology because they are systems that economize the process like M3 Hybrid. Currently, there has been not only a conceptual change but also a technological change that allows us to scan the pieces in production and in the laboratory in an agile way. In addition, years ago we did not have systems capable of storing or processing as much data as we have now; Technological development has been vital for metrology to be part of the added value of a process.

Adidas