Hendrie Viktor, Regional Director of ZEISS South East Asia

Productivity isn't a new topic in South East Asia's manufacturing industry. However, South East Asia still ranks low in terms of workforce productivity, said Hendrie Viktor, Regional Director of ZEISS South East Asia’s strategic business unit Industrial Quality Solutions to Kathryn Gerardino-Elagio of International Metalworking News for Asia during an interview in Metalex Thailand.

“Much of the manufacturing growth in the region is still largely driven by low labour cost. Pursuing that as a strategy is neither a long term nor a competitive solution,” Hendrie explained. He said manufacturers must move away from simply adding more people to increase output, and that technology may offer a more sustainable, robust and ultimately productive alternative if applied correctly and in the right areas.

“Alternative inspection methods to improve throughput is an opportunity for companies in South East Asia to increase productivity and competitiveness” Hendrie added.

Multi-purpose measuring machine

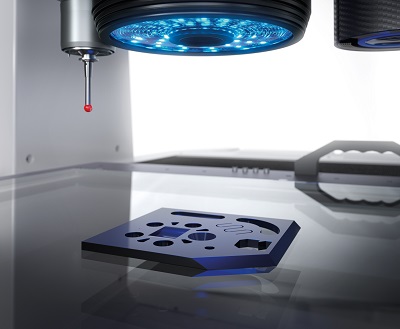

Hendrie uncorked a small geyser of news with ZEISS’s multi-sensor measuring machine, the ZEISS O-INSPECT with chromatic white light sensor called the ZEISS DotScan, demonstrated for the first time with an integrated rotary table in Metalex Bangkok.

“I admit, it sounds quite complicated but it’s basically the multi-sensor, multi-purpose measuring machine made even more versatile. This setup allows for more applications and different kinds of parts to be measured, all on a single measuring system. The purpose of this is to avoid the need for setting up and measuring on multiple machines thus saving time and money,” he said.

Hendrie revealed that a big part of its business in South East Asia is consultative selling. “What is most important is for us to truly understand our customer’s applications or pain points in quality. Quality and process verification plays an ever-increasing role in manufacturing and ZEISS has various solutions that can solve some of these challenges. But for us, it always starts with a deep understanding of the customer’s needs,” he declared.

Productivity is a function of efficiency. According to Hendrie, the drive towards increased productivity is very evident in the region. Robust yet flexible inspection and ever closer to production is key to significant quality and efficiency gains.

“If you look at manufacturing, you will see that it has become a whole lot more complex. New technologies like additive manufacturing has opened a whole new world in terms of part material and geometry and this must be verified differently as opposed to those parts manufactured with conventional machining methods.” Hendrie added.

The constant change and complexity coming into manufacturing demands a different kind of measuring machine. “We firmly believe a multi-sensor measuring machine is the future. It brings a lot of time and space savings through eliminating the need for multiple measuring devices and it enables one to measure more complex features previously not possible” he stated.

“Witnessing the 4th industrial revolution first hand and in a market as dynamic and with so much potential as South East Asia is a great honour. We are very excited about the future of this region.”

Productivity drives the development throughput of a manufacturing company. The higher the productivity, the greater the output. Throughput is a measure of how much product a plant churns out during a given period of time. The only way manufacturing companies in South East Asia are going to attain or maintain competitiveness is to invest into productivity-enhancing and efficiency-improving machines and equipment. ZEISS on the other hand is at the forefront of providing all the necessary options for reliable measurements.

ZEISS O-INSPECT with chromatic white light sensor, called the ZEISS DotScan

Nike News