Solvay has announced the launch of SolvaLite® 716 FR, an innovative fast-curing epoxy prepreg system designed for a wide range of structural parts and reinforcements in premium battery electric vehicles (BEVs).

“The automotive industry sees a need for new material solutions for battery components with superior flame retardancy compared to conventional thermoset prepregs and aluminum, and which allow passengers sufficient escape time in the event of a thermal runaway,” explains Stefano Montani, Transportation Marketing Manager at Solvay. “Structural battery housing solutions must also ensure reliable EMI shielding performance and enable efficient processing of large volumes at high production rates. Our new SolvaLite® prepreg combines all these properties with a significant lightweighting potential compared to incumbent solutions.”

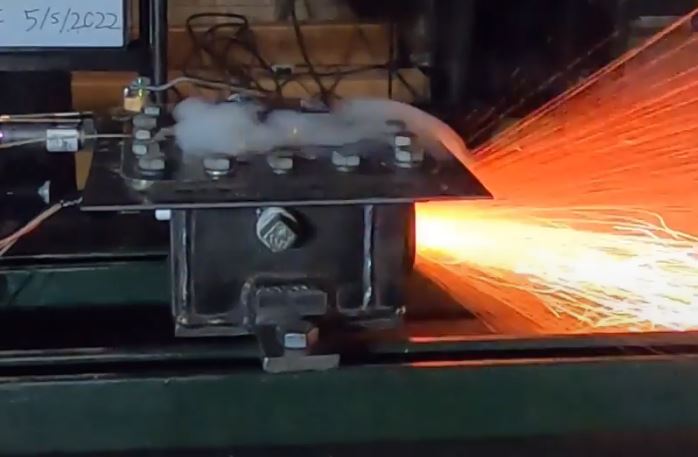

SolvaLite® 716 FR is primarily targeted at flame-retardant battery enclosure applications for premium and super-premium BEVs. It has a dry glass transition temperature (Tg) of 145°C (293°F) and has shown to outperform aluminum and discontinuous fiber composites in practical UL 2596 flammability tests by providing protection at a wall thickness of 2mm. Beyond the automotive industry, the new material also opens up a wide potential for other components where fire safety is key to meeting general UL94 V-0 specifications.

This system is designed for rapid curing, offering a press cure time of eight minutes at 150°C (302°F); with higher temperature and shorter cycle time capability designed to help converters achieve more efficient production routes, such as Solvay’s proprietary Double Diaphragm Forming (DDF) technology. SolvaLite® 716 FR is available in a carefully selected range of formats and continuous fiber types aimed at meeting the most demanding mechanical requirements, under worst-case loading conditions, minimizing component thicknesses and optimizing enclosure volume for increased volumetric energy density or vehicle z-height.

SolvaLite® 716 FR will be commercially available by the end of 2023 and will be officially launched at the upcoming CAMX Composites and Advanced Materials Expo in Atlanta from October 30 to November 02, where Solvay will be exhibiting at booth W46.

In addition, Stefano Montani and Solvay’s Senior Customer Technical Development Engineers Dhaval Jetavat and David Hulme will host a webinar on Fast-Cure Epoxy Solutions for High Volume Battery Enclosures and Body Panels at 17:00 hours CET on November 30, 2023.