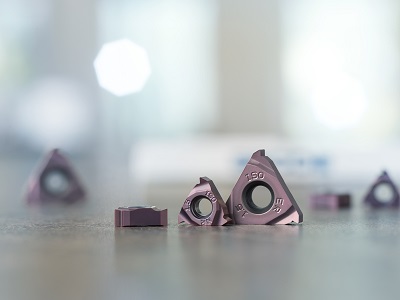

The advanced coating and tool geometry of the new TTP2050 threading insert grade from Seco Tools offers efficient, secure, stable performance, along with the effective chip control necessary to prevent threading chips from ruining critical parts in the final phases of production.

The TTP2050 grade's nano-laminate PVD coating, made from alternating layers of titanium aluminum nitride (TiAlN) and titanium silicon nitride (TiSiN), offers the extreme wear resistance required to machine cast irons, tool steels, stainless steels and other challenging steels. This chemistry exceeds the capabilities of the general-purpose coatings often used in threading operations, while the TTP2050 grade's tool geometry delivers performance reliability for increased productivity in those materials.

The TTP2050 threading grade is available in 44 profiles with geometry -A, in 11 mm and 16 mm (0.433" and 0.650") sizes. The new grade comes in both internal and external threading for all standard, common thread profiles.

For more information on the TTP2050 threading grade, please contact a local Seco representative or visit our TTP2050 threading grade product page.

Headquartered in Fagersta, Sweden and present in more than 75 countries, Seco Tools is a leading global provider of metal cutting solutions for milling, stationary tools, holemaking and tooling systems. For more than 80 years, the company has provided the technologies, processes and support that manufacturers depend on for maximum productivity and profitability. For more information on how Seco’s innovative products and expert services bring success to manufacturers across all industry segments, please visit www.secotools.com

Nike Shox Avenue 808