Laser welding applications range from assembly of precision electronic components to welding of large automotive composite blanks. Lasers cut by concentrating light energy on the surface of a workpiece, heating it so that it melts, vaporises or decomposes. An assist gas, delivered through a nozzle coaxial with the laser beam, removes the material. Laser power, spot size, focal position, travel speed and the assist gas are the important variables. Using the right assist gas avoids dross and rough edges. Oxygen is generally used as an assist gas when laser cutting carbon steel. Here, the laser beam acts as a precise pilot flame, as in conventional oxyfuel gas cutting. The exothermic reaction of iron and oxygen adds energy. Most of the laser cutting done for metal fabrication is in low-carbon steel of .125-inch (3.18 mm) thickness or less with a typical dimensional tolerance of .005-inch (.13 mm). A 500-watt laser is effective for much of this work. Powerful lasers of 5 kW or more can cut stock an inch thick or more, but there is a potential problem with heat build-up, often called 揵urnout.?If the workpiece temperature rises too much, the heat build-up causes a reaction to occur away from the laser beam, causing a rough wide kerf. To reduce the problem, try applying a fine spray of water to the workpiece to cool the metal, so that it will not react with oxygen other than at the laser spot. This allows intricate cuts in thick steel plate. A good way to apply water is with a cutting head having an annular water nozzle surrounding the assist gas nozzle. For stainless steel, nitrogen or argon assist gases yield clean, weldable edges with minimal heat-affected zones (HAZ). Cutting many difficult materials including aluminium, titanium and nickel-base super alloys requires inert assist gases. Precision laser cuttings are more popular and effective than the traditional cutting process. The reason is obvious. Its accuracy holds the key to success of precision laser cutting. In the manufacturing industry, quality and accuracy are very important aspect; precision laser cutting is an excellent tool. The benefit of laser cutting is far too many. It is not only flexible and fast but it is a cost-effective mechanism as well. In precision laser cutting the material does not come into contact with the cutting tool. While in the traditional method of cutting, the material has a physical contact with the cutting tool. Classifying lasers 晻Class 1 describes that do not, under normal operating conditions, pose a hazard. 晻Class 2 indicate low-power visible lasers which, because of the normal human aversion response (i.e., blinking and eye movement), do not normally present a hazard, but may possibly present some potentialnike sb

Laser welding applications range from assembly of precision electronic components to welding of large automotive composite blanks. Lasers cut by concentrating light energy on the surface of a workpiece, heating it so that it melts, vaporises or decomposes. An assist gas, delivered through a nozzle coaxial with the laser beam, removes the material. Laser power, spot size, focal position, travel speed and the assist gas are the important variables. Using the right assist gas avoids dross and rough edges. Oxygen is generally used as an assist gas when laser cutting carbon steel. Here, the laser beam acts as a precise pilot flame, as in conventional oxyfuel gas cutting. The exothermic reaction of iron and oxygen adds energy. Most of the laser cutting done for metal fabrication is in low-carbon steel of .125-inch (3.18 mm) thickness or less with a typical dimensional tolerance of .005-inch (.13 mm). A 500-watt laser is effective for much of this work. Powerful lasers of 5 kW or more can cut stock an inch thick or more, but there is a potential problem with heat build-up, often called 揵urnout.?If the workpiece temperature rises too much, the heat build-up causes a reaction to occur away from the laser beam, causing a rough wide kerf. To reduce the problem, try applying a fine spray of water to the workpiece to cool the metal, so that it will not react with oxygen other than at the laser spot. This allows intricate cuts in thick steel plate. A good way to apply water is with a cutting head having an annular water nozzle surrounding the assist gas nozzle. For stainless steel, nitrogen or argon assist gases yield clean, weldable edges with minimal heat-affected zones (HAZ). Cutting many difficult materials including aluminium, titanium and nickel-base super alloys requires inert assist gases. Precision laser cuttings are more popular and effective than the traditional cutting process. The reason is obvious. Its accuracy holds the key to success of precision laser cutting. In the manufacturing industry, quality and accuracy are very important aspect; precision laser cutting is an excellent tool. The benefit of laser cutting is far too many. It is not only flexible and fast but it is a cost-effective mechanism as well. In precision laser cutting the material does not come into contact with the cutting tool. While in the traditional method of cutting, the material has a physical contact with the cutting tool. Classifying lasers 晻Class 1 describes that do not, under normal operating conditions, pose a hazard. 晻Class 2 indicate low-power visible lasers which, because of the normal human aversion response (i.e., blinking and eye movement), do not normally present a hazard, but may possibly present some potentialnike sbNuts and bolts of laser welding

Source: Release Date:2009-09-14 117

Add to Favorites

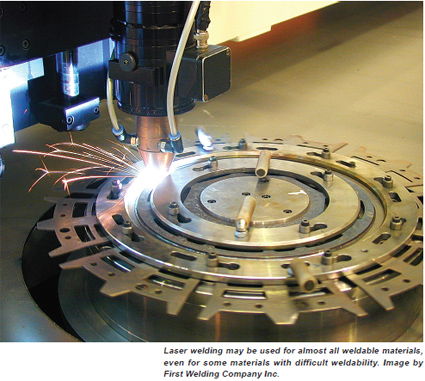

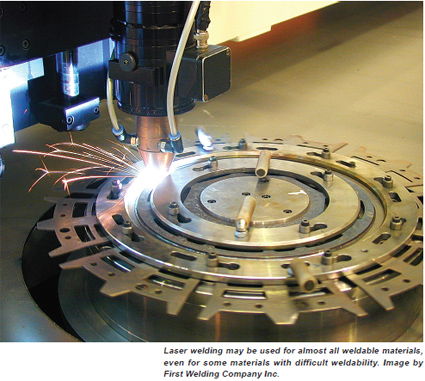

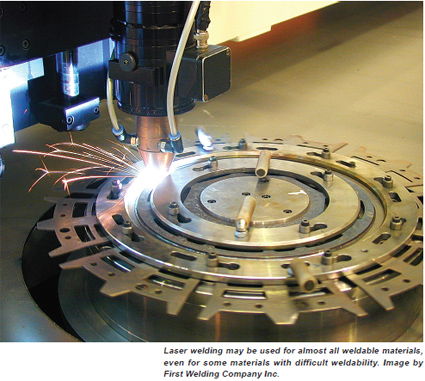

In the world of high technology such as laser welding, knowing some few basic technical things about the industry will help ensure that the process is being maximised in your shop. A thorough grasp of the basics is critical to the success of any laser welding project. Laser welding is the most advanced manufacturing technology that is rapidly gaining popularity. Be it in any industry, military, medical, aerospace engineering, automotive, space propulsion or hi-tech manufacturing, processing by laser beams have immense benefits and is the best solution to organisational needs and manufacturing equipments as precision laser cutting leads to accuracy and perfection. High-powered CNC laser cutting and welding machines provide several important advantages for short-run and prototype part production including economic production of small lots of flat parts complete with holes can be performed without building a die. Blank development can be done much faster and with greater accuracy than can be done with band saws or hand shears. Lasers can trim drawn or formed panels and can create irregular cut-outs on them when combined with a five-axis positioning gantry.  Laser welding applications range from assembly of precision electronic components to welding of large automotive composite blanks. Lasers cut by concentrating light energy on the surface of a workpiece, heating it so that it melts, vaporises or decomposes. An assist gas, delivered through a nozzle coaxial with the laser beam, removes the material. Laser power, spot size, focal position, travel speed and the assist gas are the important variables. Using the right assist gas avoids dross and rough edges. Oxygen is generally used as an assist gas when laser cutting carbon steel. Here, the laser beam acts as a precise pilot flame, as in conventional oxyfuel gas cutting. The exothermic reaction of iron and oxygen adds energy. Most of the laser cutting done for metal fabrication is in low-carbon steel of .125-inch (3.18 mm) thickness or less with a typical dimensional tolerance of .005-inch (.13 mm). A 500-watt laser is effective for much of this work. Powerful lasers of 5 kW or more can cut stock an inch thick or more, but there is a potential problem with heat build-up, often called 揵urnout.?If the workpiece temperature rises too much, the heat build-up causes a reaction to occur away from the laser beam, causing a rough wide kerf. To reduce the problem, try applying a fine spray of water to the workpiece to cool the metal, so that it will not react with oxygen other than at the laser spot. This allows intricate cuts in thick steel plate. A good way to apply water is with a cutting head having an annular water nozzle surrounding the assist gas nozzle. For stainless steel, nitrogen or argon assist gases yield clean, weldable edges with minimal heat-affected zones (HAZ). Cutting many difficult materials including aluminium, titanium and nickel-base super alloys requires inert assist gases. Precision laser cuttings are more popular and effective than the traditional cutting process. The reason is obvious. Its accuracy holds the key to success of precision laser cutting. In the manufacturing industry, quality and accuracy are very important aspect; precision laser cutting is an excellent tool. The benefit of laser cutting is far too many. It is not only flexible and fast but it is a cost-effective mechanism as well. In precision laser cutting the material does not come into contact with the cutting tool. While in the traditional method of cutting, the material has a physical contact with the cutting tool. Classifying lasers 晻Class 1 describes that do not, under normal operating conditions, pose a hazard. 晻Class 2 indicate low-power visible lasers which, because of the normal human aversion response (i.e., blinking and eye movement), do not normally present a hazard, but may possibly present some potentialnike sb

Laser welding applications range from assembly of precision electronic components to welding of large automotive composite blanks. Lasers cut by concentrating light energy on the surface of a workpiece, heating it so that it melts, vaporises or decomposes. An assist gas, delivered through a nozzle coaxial with the laser beam, removes the material. Laser power, spot size, focal position, travel speed and the assist gas are the important variables. Using the right assist gas avoids dross and rough edges. Oxygen is generally used as an assist gas when laser cutting carbon steel. Here, the laser beam acts as a precise pilot flame, as in conventional oxyfuel gas cutting. The exothermic reaction of iron and oxygen adds energy. Most of the laser cutting done for metal fabrication is in low-carbon steel of .125-inch (3.18 mm) thickness or less with a typical dimensional tolerance of .005-inch (.13 mm). A 500-watt laser is effective for much of this work. Powerful lasers of 5 kW or more can cut stock an inch thick or more, but there is a potential problem with heat build-up, often called 揵urnout.?If the workpiece temperature rises too much, the heat build-up causes a reaction to occur away from the laser beam, causing a rough wide kerf. To reduce the problem, try applying a fine spray of water to the workpiece to cool the metal, so that it will not react with oxygen other than at the laser spot. This allows intricate cuts in thick steel plate. A good way to apply water is with a cutting head having an annular water nozzle surrounding the assist gas nozzle. For stainless steel, nitrogen or argon assist gases yield clean, weldable edges with minimal heat-affected zones (HAZ). Cutting many difficult materials including aluminium, titanium and nickel-base super alloys requires inert assist gases. Precision laser cuttings are more popular and effective than the traditional cutting process. The reason is obvious. Its accuracy holds the key to success of precision laser cutting. In the manufacturing industry, quality and accuracy are very important aspect; precision laser cutting is an excellent tool. The benefit of laser cutting is far too many. It is not only flexible and fast but it is a cost-effective mechanism as well. In precision laser cutting the material does not come into contact with the cutting tool. While in the traditional method of cutting, the material has a physical contact with the cutting tool. Classifying lasers 晻Class 1 describes that do not, under normal operating conditions, pose a hazard. 晻Class 2 indicate low-power visible lasers which, because of the normal human aversion response (i.e., blinking and eye movement), do not normally present a hazard, but may possibly present some potentialnike sb

Laser welding applications range from assembly of precision electronic components to welding of large automotive composite blanks. Lasers cut by concentrating light energy on the surface of a workpiece, heating it so that it melts, vaporises or decomposes. An assist gas, delivered through a nozzle coaxial with the laser beam, removes the material. Laser power, spot size, focal position, travel speed and the assist gas are the important variables. Using the right assist gas avoids dross and rough edges. Oxygen is generally used as an assist gas when laser cutting carbon steel. Here, the laser beam acts as a precise pilot flame, as in conventional oxyfuel gas cutting. The exothermic reaction of iron and oxygen adds energy. Most of the laser cutting done for metal fabrication is in low-carbon steel of .125-inch (3.18 mm) thickness or less with a typical dimensional tolerance of .005-inch (.13 mm). A 500-watt laser is effective for much of this work. Powerful lasers of 5 kW or more can cut stock an inch thick or more, but there is a potential problem with heat build-up, often called 揵urnout.?If the workpiece temperature rises too much, the heat build-up causes a reaction to occur away from the laser beam, causing a rough wide kerf. To reduce the problem, try applying a fine spray of water to the workpiece to cool the metal, so that it will not react with oxygen other than at the laser spot. This allows intricate cuts in thick steel plate. A good way to apply water is with a cutting head having an annular water nozzle surrounding the assist gas nozzle. For stainless steel, nitrogen or argon assist gases yield clean, weldable edges with minimal heat-affected zones (HAZ). Cutting many difficult materials including aluminium, titanium and nickel-base super alloys requires inert assist gases. Precision laser cuttings are more popular and effective than the traditional cutting process. The reason is obvious. Its accuracy holds the key to success of precision laser cutting. In the manufacturing industry, quality and accuracy are very important aspect; precision laser cutting is an excellent tool. The benefit of laser cutting is far too many. It is not only flexible and fast but it is a cost-effective mechanism as well. In precision laser cutting the material does not come into contact with the cutting tool. While in the traditional method of cutting, the material has a physical contact with the cutting tool. Classifying lasers 晻Class 1 describes that do not, under normal operating conditions, pose a hazard. 晻Class 2 indicate low-power visible lasers which, because of the normal human aversion response (i.e., blinking and eye movement), do not normally present a hazard, but may possibly present some potentialnike sb

Laser welding applications range from assembly of precision electronic components to welding of large automotive composite blanks. Lasers cut by concentrating light energy on the surface of a workpiece, heating it so that it melts, vaporises or decomposes. An assist gas, delivered through a nozzle coaxial with the laser beam, removes the material. Laser power, spot size, focal position, travel speed and the assist gas are the important variables. Using the right assist gas avoids dross and rough edges. Oxygen is generally used as an assist gas when laser cutting carbon steel. Here, the laser beam acts as a precise pilot flame, as in conventional oxyfuel gas cutting. The exothermic reaction of iron and oxygen adds energy. Most of the laser cutting done for metal fabrication is in low-carbon steel of .125-inch (3.18 mm) thickness or less with a typical dimensional tolerance of .005-inch (.13 mm). A 500-watt laser is effective for much of this work. Powerful lasers of 5 kW or more can cut stock an inch thick or more, but there is a potential problem with heat build-up, often called 揵urnout.?If the workpiece temperature rises too much, the heat build-up causes a reaction to occur away from the laser beam, causing a rough wide kerf. To reduce the problem, try applying a fine spray of water to the workpiece to cool the metal, so that it will not react with oxygen other than at the laser spot. This allows intricate cuts in thick steel plate. A good way to apply water is with a cutting head having an annular water nozzle surrounding the assist gas nozzle. For stainless steel, nitrogen or argon assist gases yield clean, weldable edges with minimal heat-affected zones (HAZ). Cutting many difficult materials including aluminium, titanium and nickel-base super alloys requires inert assist gases. Precision laser cuttings are more popular and effective than the traditional cutting process. The reason is obvious. Its accuracy holds the key to success of precision laser cutting. In the manufacturing industry, quality and accuracy are very important aspect; precision laser cutting is an excellent tool. The benefit of laser cutting is far too many. It is not only flexible and fast but it is a cost-effective mechanism as well. In precision laser cutting the material does not come into contact with the cutting tool. While in the traditional method of cutting, the material has a physical contact with the cutting tool. Classifying lasers 晻Class 1 describes that do not, under normal operating conditions, pose a hazard. 晻Class 2 indicate low-power visible lasers which, because of the normal human aversion response (i.e., blinking and eye movement), do not normally present a hazard, but may possibly present some potentialnike sb Add to Favorites

You May Like