GEA has begun the installation of two complete lines for the production of freeze-dried and spray-dried instant coffee using the CARINE extraction system for its customer, olam food ingredients (ofi) in Brazil.

ofi's new coffee plant will start production in 2023. It is built on a greenfield site in Espírito Santo, Brazil, a region that produces conilon beans, which are similar to robusta. This facility will be one of the largest GEA has ever built and will give ofi capabilities for significant future growth in its soluble coffee business.

ofi is a new operating group born out of Olam. The company offers sustainable, natural, value-added food products and ingredients and is a top-three global supplier of green coffee, with a presence in nearly all major origins. Although ofi has considerable global experience in the production of instant coffee, this will be the first time the company processes instant coffee in Brazil.

GEA's complete lines are for the production of ofi's freeze-dried and spray-dried instant coffee in Brazil (Source: ofi)

Instant coffee consumption is expected to increase in South America and the new facility will enable ofi to expand capacity to meet the demands of a growing market. According to Preben Dam, Area Sales Manager for Coffee and Freeze Drying at GEA, ofi is proving to be an industry trendsetter: “Having designed and built more than 200 instant coffee plants around the world, GEA is at the forefront of coffee processing technology. We are very pleased to be able to support ofi in its factory investment in Brazil, which is a new approach for this industry.”

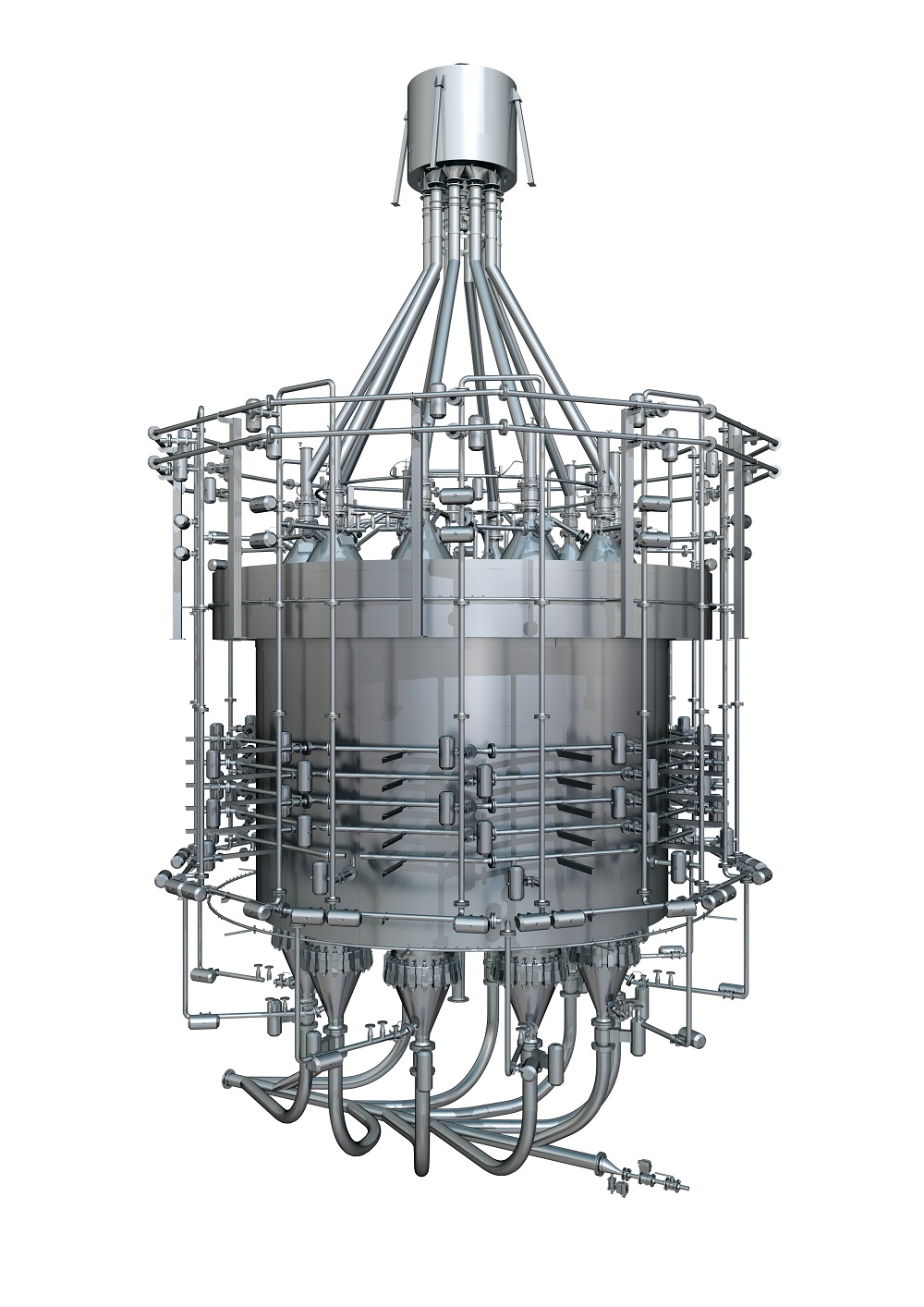

GEA extractors designed for high performance: Eliminating the need for manual operation, the compact and fully automated CARINE extractor ensures precision processing that meets the world’s highest standards.(Source: GEA)

GEA expertise and reliability make the difference

GEA secured the contract thanks to the close relationship it has established with ofi over the past ten years – with projects including the construction of three coffee plants in Vietnam – and its extensive experience in both freeze-dried and spray-dried coffee production worldwide.

Shankar Rao, SVP Head of operations at ofi says: “Our relationship with GEA started in 2007 with the construction of our first soluble coffee plant in Vietnam. Over the years GEA has upgraded their technology in the areas of extraction, evaporation and freeze drying which has not only helped us increase output but also material efficiency, a key value driver in soluble coffee manufacturing. Our focus on technical superiority, product development and innovation in the soluble coffee business will give us the capabilities for significant future growth.”

Scope of supply

GEA’s Center of Competence in Denmark will supply its CARINE extraction system, which is designed for customers wishing to obtain the highest possible yields from the production process, for both lines. The CARINE system’s efficiency was one of the main reasons for ofi choosing to partner with GEA again to construct the two complete production lines. The order also includes GEA MVR (mechanical vapor recompression) evaporation technology, GEA CONRAD® freeze drying equipment and a refrigeration plant. Close collaboration across the GEA network ensures that ofi receives the technical specialist on its side for every aspect of the project.