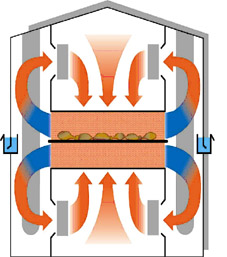

How It Works: ?Hot humid air is uniformly applied across conveyor. ?Return path of air between impingement nozzles does not interfere with incoming hot air. ?Plenum-mounted fans above and below the conveyor force air through nozzles evenly onto product.

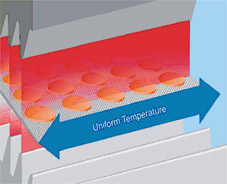

The technology driving the Airforce?Impingement Oven from Heat and Control uses indirect heat to provide a precise and consistent cooking environment that increases cooking time and improves quality. A uniform, stable airflow across the width of the entire cooking area or conveyor belt ensures that each individual product piece is identically cooked regardless of its position in the oven. This prevents product discoloration or 損inking?that can affect the internal and external attributes like color, texture and taste of the finished product as well as reducing wastage due to over or undercooking. The Airforce offers flexibility and precise settings for different types of food products. Temperature, humidity and air velocity are independently adjustable above and below the product via the programmable recipe control system and the upper air nozzles are adjustable 50mm to 200mm above the conveyor allowing product heights of up to 150mm. Simple and easy to use automated process control and data management allows fine-tuning of conditions such as temperature, fan speed and belt speed.

Heat is distributed evenly across the entire cooking area to ensure each product piece is identically cooked

All internal surfaces are fully accessible and require minimal time to clean using the computer controlled clean-in-place system and the absence of air ducts or insulated panels prevent collection of bacteria. The oven's conveyor and air nozzles separate when the hood is raised providing easy access for cleaning while dual rotary brushes continuously clean the conveyor belt during operation. Combined with the MPO?Convection or microwave ovens, steam chambers, fryers, Rotary Branders or coating applicators, the Airforce offers maximum versatility and higher product yield for meat, poultry, seafood, vegetables and baked products processing.Max 90 Winter Sneakerboot