The major sectors of the PET container market that utilise one‐step injection stretch blow moulding process today include cosmetics, personal care, pharmaceutical, household and general food packaging, etc. where containers are more commonly designed for market appeal and brand quality, resulting in preform design that up to now has been a compromise between container quality and moulding efficiency.

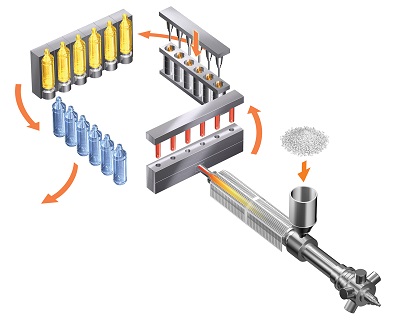

First announced in 2018, Zero Cooling ‐ Nissei ASB’s revolutionary advance in preform cooling technology ‐ perfectly suits the needs of these industries as it enables increased product quality at significantly shorter moulding cycles than seen previously. Taking full advantage of ASB’s proprietary 4‐station, 1‐step moulding method, virtually all the required preform cooling is now shifted away from the injection station and into the second, conditioning station to dramatically reduce injection cycle times. Crucially, the Zero Cooling moulding method enables these short cycle times to be achieved while avoiding the need for thin, compromised design preforms that are susceptible to several quality related problems, most notably the undesirable “fisheye”, “body ring” and “orange peel”.

Now, with the preform designer able to freely focus on a shorter preform design with a thicker wall section that optimises stretch ratios, the result is vastly improved quality as well as increased productivity. Actual results from typical Zero Cooling moulds have shown 15% or greater increase in stiffness and topload strength, improved control of material distribution and an average of 1.5 times productivity increases while improving on visual quality. Furthermore, since the container strength has now been improved by better orientation, more scope is available to apply additional light-weighting to the container’s specification.

The advanced cooling method also enables the moulding of heavyweight premium cosmetic containers in dramatically shortened cycle times exhibiting no haziness even when using standard, lower cost PET grades, rather than the higher priced specialised, low‐crystallisation grades that are normally required. All this results in perfect visual quality while saving cost and boosting productivity by 2‐3 times over conventional moulding of these glass‐like, premium designs.

The Zero Cooling technology not only benefits users of ASB equipment but also demonstrate ASB’s commitment to provide high quality moulded products that help protect the natural environment. Increased productivity provided by Zero Cooling equipped moulding systems reduces the overall energy consumption per bottle. Additional container strength provided by Zero Cooling allows further opportunities for weight reductions. Moreover, two machines from ASB’s latest fleet is capable of moulding 100% R‐PET that fully confirms the ability of Zero Cooling to produce highest quality containers at high efficiency over a range of material specifications.

Versatility and expanded capability

Nissei ASB demonstrated five machines at K 2019, a reflection of how the company has taken stretch blow moulding a step higher.

The ASB‐12M v2 is a small-sized machine with vast capability. The ASB‐12M has firmly established itself as a leader in the class of small, fully automated 1‐step stretch blow moulding machines with its diminutive size belying its huge capabilities. Now in its Version 2 specification, the model brings even greater performance and utility to the table. Most notable is the Vision1 control system that elevates the machine capabilities to a whole new level offering significant advantages to users that include response and communication speed that is 2.5 times faster than dedicated PLC systems enhancing machine cycle efficiency and control precision. The revised ASB‐12M expands the capabilities for production of a vast range of PET containers, including highly efficient light‐weight bottles and wide mouthed jars, to the highest quality at low capital investment. The machine is capable of processing 20 resin types in addition to PET and can produce contains from 5ml or less all the way up to 2.5‐litres capacity.

The ASB‐70DPH v4 is a model with ultimate versatility. This mid‐range ASB‐70DPH model has been a favorite for over 30 years due to its economy, flexibility and convenient size – and due to regular technology updates, it has stayed at the forefront of 1‐step moulding technology with class leading efficiency. With the ability to mould PET and up to 20 other resin types, combined with the capacity to mould up to 10‐litre capacity jars in a single cavity all the way through to sub‐100ml bottles in up to 12 cavities, it is little surprise that this model remains the company’s bestseller.

The ASB‐70DPHv4 utilises ASB’s renowned 4‐station moulding process to achieve optimum moulding efficiency and stability of a wide range of moulding materials. It can process up to 20 resin types in addition to PET and mould containers from 50ml or less all the way up to 10 litres’ capacity. Containers can be in variable cavitation from 18mm neck diameter small bottles in 12 cavities through to 149mm neck diameter jars in a single cavity.

The ASB‐70DPH – Advanced Version may look similar to the standard version but the ASB‐70DPH Advanced Version has been fully re‐engineered to demonstrate a variety of techniques to achieve dramatically reduced indexing time that fully complements the Zero Cooling process and provides dramatically enhanced output, especially for smaller containers. The model has revised hydraulic circuit for faster, smoother motion of clamping; adjustable stroke in all clamping stations for reduced machine indexing time for shorter preforms, while adjustable daylight also allows longer preforms, a feature especially useful for many non‐PET moulding resins. Its fully revised blow station reduces index time, simplifies blow mould changeover and reduces maintenance.

With this Advanced Version machine giving a 40% reduction in indexing time, the demonstrated container using a short preform can be moulded at up to 2.4 seconds faster than that achievable by a standard model. This saving is in addition to the reduced cycle time obtained from the use of Zero Cooling technology in the mould design. Combining the aforementioned machine revisions with ASB’s Zero Cooling mould technology, the 8‐cavity, single row mould producing a 30ml, 3.8gram, 19mm screw neck container for medical or toiletry use will cycle at 4.4 seconds to provide over 6,500bph.

The ASB‐70DPW v4 features high output of small containers in various resins. The double‐row moulding equivalent to the ASB‐70DPH is optimised for production of smaller bottles in moulding configurations from 8 to 24 cavities for high productivity of containers up to 1‐litre capacity. Assisting with energy saving, the servo hydraulic system provides power consumption savings of 30‐40% compared to the same mould and cycle time running in a conventional machine, while an optional blow air recycle system has the capability to take exhausted blowing air back into the machine system for air cylinder operation thus saving energy at the operation (low pressure) air compressor. For a blow mould change, just 30% of the previous time is required while for a total and complete preform and blow mould change, around 50% of the previous time is required. The machine can process 100% recycled PET.

The ASB‐150DPW is the largest model in the ASB‐150 Series that operates using single, double or triple row moulding. Despite being a high productivity machine for small to medium sized containers, the double row layout of the ASB‐150DPW also has the versatility to mould a wide variety of bottles and jars in PET and other resins, such as PP infusion bottles, to satisfy a wide range of users’ needs. Output is typically around 2.5 times that of the smaller ASB‐70DPW. Energy consumption is maintained very low due to the adoption of standard variable displacement or optional servo driven hydraulic pumps. The ASB‐150DPW is capable to mould containers from 1.5‐litre jars with 94mm necks to sub‐150ml bottles ranging from 8 to 36 cavities.