At the 2019 Asia Manufacturing Summit organised by Ringier Events in Jakarta, Indonesia, one of the resource persons provided an interesting presentation on the production of uniquely sustainable pallets and how the production process for this product can help in Indonesia’s efforts towards recycling. Representing Asociasi Daur Ulang Plastik Indonesia (ADUPI) or the Indonesian Plastics Recycling Association, Mr. Andrianto Gunawan, Head of Procurement of Pt. REPAL International Indonesia, discussed the problem of recycling in Indonesia and how Re>Pal is addressing the obstacles and challenges faced by the country in encouraging sustainable production.

Mr. Gunawan shares with International Plastics News for Asia (IRNA) his insights on recycling and some solutions that can be undertaken.

Mr. Andrianto Gunawan, Head of Procurement of Pt. REPAL Internasional Indonesia

IRNA: Before we proceed with Re>Pal , please tell us first about ADUPI and its objectives.

Mr. Gunawan: ADUPI or the Indonesian Plastics Recycling Association was established in 2015 in Surabaya, East Java. The association was founded by plastic recycling entrepreneurs with the goal of creating a conducive recycling business by working with all the stakeholders. At present, ADUPI has eight regional representative offices located in Greater Jakarta, West Java, Central Java, Jogja, Solo and East Java, West Nusa Tenggara, Papua.

ADUPI’s vision is to become a beneficial association for its members and the Indonesian government to create and implement a prevention programme to alleviate plastic waste pollution on the environment. The association’s mission is to fight for members' aspirations, and increase cooperation and communication between members with the Indonesian government. It also works to improve services and help members by providing direction related to government policy.

IRNA: How important is recycling to Indonesia and what are the challenges that the country and the recyclers face now?

Mr. Gunawan: Indonesia currently faces a monumental task as far as plastic waste recycling is concerned. The amount of garbage generated by its population is so huge and the main cause of this problem stems in human behaviour, and not really on the plastic products. Unfortunately, the waste management system in Indonesia is not working.

To date, the country has around 5 million pickers who are part of the recycling chain and these pickers belong to the informal sector which has a big impact in the recycling process. Despite the presence of these pickers, the problem of collection and sorting of waste has not been resolved due to high cost and absence of necessary infrastructure. Also, as I’ve said, the attitude and lack of cooperation among the people remains the biggest challenge.

On the part of the government, there is the Waste Management Law No. 18/2008 which aims to institute a systematic waste management system but the law is not being implemented due to several factors and one of them is the misunderstanding and misinterpretation on the purpose of the law, especially on the ban in the use of plastic bag, straws and styrofoams. Local government units lack an understanding and sufficient knowlege on waste management, in particular, plastics.

If I may add, there are certain regulations, like the imposition of the value-added tax (VAT), which are a burden to the recycling industry. While for producers, their Corporate Social Responsibility (CSR)/Extended Producer Responsibility (EPR) are not well-defined and managed properly. “Green washing” or the practice of misleading claim on the materials – biodegradable, oxo-biodegradable, compostable – is also adding to the many challenges in Indonesian plastics recycling sector.

IRNA: How is Re>Pal related to the country’s goal to achieve a circular economy in plastics?

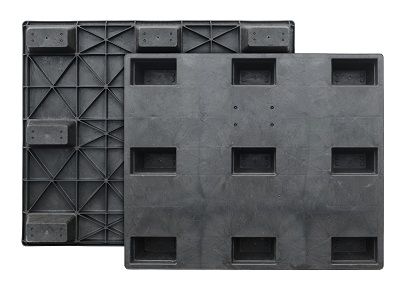

Mr. Gunawan: Re>Pal is a cost-effective pallet solutions. As I’ve said in my presentation, Re>Pal is uniquely sustainable because it is made from 100% recycled plastic waste, while at the same time providing lifetime value and aids in reducing logistics risks

Using state-of-the art pallet technology, the company offers environtmentally-responsible pallets for a wide range of applications across business supply chains throughout the South East Asian export-hub and Australian region.

Re>Pal pallet is made from 100% recycled plastic waste.

IRNA: What makes Re>Pal extraordinary?

Mr. Gunawan: Re>Pal zero waste pallets are made from 100% waste plastic using a unique technology process, which we call ThermoFusion™. Re>Pal pallets improve our customers’ profitability while enabling them to operate sustainably through leveraging the low energy, environtmentally-friendly, and adopting a cost-effective solution.

Re>Pal manages and supplies its superior pallets to many global and domestic suppliers, including Unilever, IndoFood, Nestle and IFF, and other businesses interested in offsetting their carbon footprint without compromising on quality or profitability.

With the ThermoFusion™ process, Re>Pal has a unique approach to managing plastic waste. We are able to generate a structurally strong ISO tested (ISO8611) product from a variety of mixed waste inputs. Our process also uses a minimal amount of energy compared to virgin plastic or timber pallet manufacture. Re>Pal’s ThermoFusion™ pallets offer businesses both profitability and sustainability in the form of a carbon neutral, environtmentally-friendly, well designed and efficient freighting solution.

Plastics that can be recycled using this process include high density polyethylene (HDPE) such as shopping & groceries bags, Ziploc bags, bread bags, newspaper bags, bubble wraps, milk bottles & caps, and shampoo, conditioner & liquid soap bottles. It can also process low density polyethylene (LDPE) such as garbage bags, irrigation pipes, squeeze bottles, packaging films, agricultural films, laundry bags; as well as polypropylene (PP) such as crates, drinking straws, tarpaulins, plant pots and more.

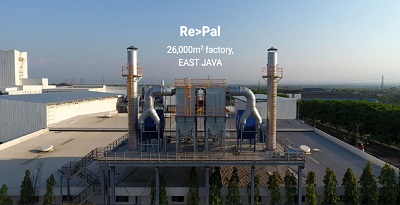

Re>Pal’s main factory is located in East Java, Indonesia.

IRNA: What are the notable advantages of using Re>Pal pallets?

Mr. Gunawan: Re>Pal pallets is a zero waste solution that enables our customers to meet their sustanaible development goals and create a circular economy in plastics by closing the loop with a 100% recyclable pallets. Our pallets guarantee superior lifetime costs as compared to wooden pallets that are deemed wasteful, inefficient and poses high logistics risk. With its pallets, Re>Pal can help customers reduce logistics risk through zero waste future. inspection time & cost.

IRNA: What are the various types of Re>Pal pallets available today?

Mr. Gunawan: There are many different types of pallets globally, with different countries and continents having their own standard dimensions and some larger organisations even designing customised pallets to suit their particular purpose. From its extensive East Java factory, Re>Pal has its own in-house design and engineering teams to provide customised products for larger multi-national, pan-Asia clients that have significant pallet volumes, For standard products, Re>Pal provides for four key pallet categories: in the nestable, nestable stackable, rackable and heavy duty pallet categories suitable for exports, logistics and warehousing. IRNA

Pt REPAL Internasional Indonesia

Tel: +61-2 8280 7355; +62 21 2939 8953

E-mail: vincent.gunawan@re-pal.com; sales@re-pal.com

Website: https://re-pal.com