The SwissNano 7 machine has proven its worth for many customers and it excels in the machining of parts for the medical and dental fields, as well as the electronics and micro-mechanics industries. It can optimize workpiece production in workshops. So, let’s take a brief look at how it manages to do so.

Floor space

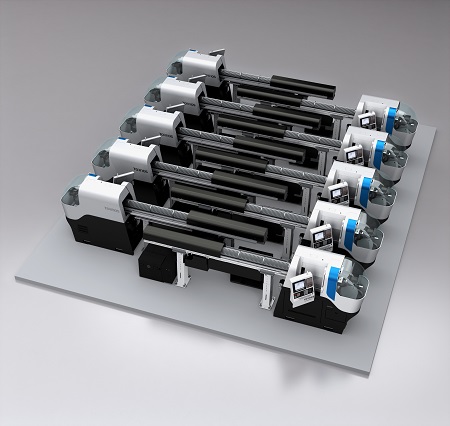

This aspect is eye-catching: With its length of 3 meters and its 1-meter width, the SwissNano 7 is extremely compact. This machine configuration even includes a high-pressure pump. So, a workshop can accommodate 10 machines on a floor space of less than 80 square meters. Since the machines have spindles equipped with optimized motor drives, heat dissipation is very low. The workshop benefits from this in terms of reduced power consumption and less technical effort required to dissipate heat. For workshops with air conditioning, the electricity bill will be much lower. To enhance the machine heating characteristics, the spindles are equipped with an integrated cooling circuit. With a view to optimum thermal characteristics, both the spindles and the rotating guide bush are provided with ceramic bearings.

Thermal behaviour

The SwissNano has short thermal circuits. This is the basis of a machine concept which mainly consists of a symmetrical cast-iron core that allows perfect control over thermal variations of the machine – with quite simple results. According to various customers interviewed, the stabilization of the SwissNano 7 takes no more than 5 minutes even under the most adverse conditions (i.e. with a cold machine). So, this small machine can provide maximum productivity from the first workpieces while the scrap rate is kept extremely low. In addition to its favourable thermal behaviour, the machine offers utmost rigidity. The wear resistance of the tools is excellent and permits cost savings of sometimes more than 30% on cutting tools. The structure of the machine and its base is simply perfect; it provides quick stabilization and ultra-rigidity.

Production efficiency

In the production process, the SwissNano 7 machine features a marvellous dimensional stability and utmost productivity. Thanks to its footprint, its tooling system and its kinematic system, the machine achieves a higher productivity than more complex and more expensive machines. The differences have been made out by one of the first customers where the SwissNano 7 produces 650 parts per shift and achieves a daily throughput of 1300 workpieces, given the fact that the company is operating in 2 shifts. The previous machines used, came from a famous European manufacturer of automatic lathes. Despite its 2 supplementary tool systems and its higher theoretical performance, the competitive machine can only produce 350 parts per shift. In this case, the small SwissNano 7 is therefore 85% faster. One could also say that the customer needs three competitive machines to achieve the annual production of one SwissNano 7 machine. And what’s more, the SwissNano’s scrap rate is much lower.

Workpiece quality and unloading

Thanks to its pooled machining capabilities, the SwissNano 7 allows a drastic scrap rate reduction. The extremely well-thought-out machine core contributes to the overall quality of the machine. Often, it is very difficult to unload the parts correctly without damaging them. Here, the SwissNano 7 offers an excellent solution. It can be equipped with a vacuum system, a carousel that enables workpiece sorting and convenient statistical monitoring. The machine is suitable for all types of workpieces and the part outlet in the machining area can also be adapted to the specific workpiece requirements. With its high performance, flexibility and efficiency, the SwissNano is an excellent partner. Do not hesitate to discover it through your nearest Tornos representation.