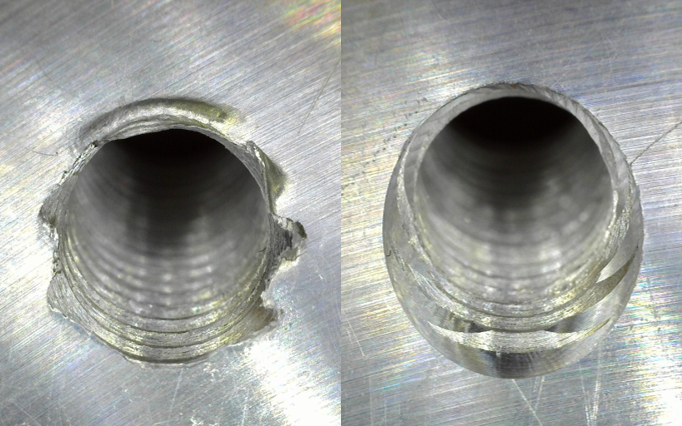

The left is the image of conventional manual deburring method. The right is the after deburring image of XEBEC Back Burr Cutter and Path for Tapped Hole.

A tapped hole is one of the most challenging parts in terms of deburring. While in most production facilities, deburring of tapped holes continues to be processed manually, XEBEC took on the challenge to automate the process and finally came up with the CNC deburring solution.

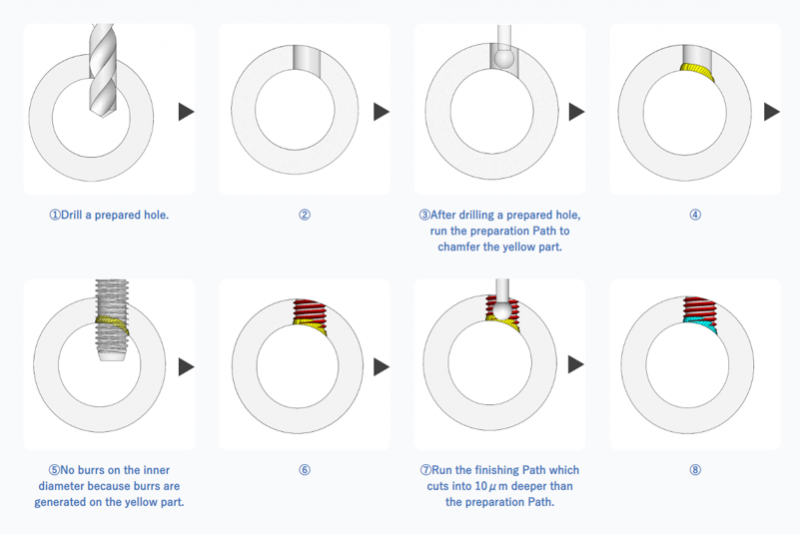

The solution works in combination of the uniquely designed spherical deburring cutter with the custom-made tool path (point group data). The tool path is tailor-made for a designated 3D-curved edge profile and can be used right away after being installed in the NC program. Thus, a user can save time to program on their own.

This innovative solution guarantees high-speed and high-precision deburring without secondary burr formation, while reducing the cycle time, tool and labor cost. Since the contact point of the cutter is continuously shifting while contouring an edge, the tool wear is dramatically reduced, causing 5 to 10-times longer tool life compared to conventional deburring tools. This is applicable for M3-M24 tapped holes, thus supporting a vast range of industries, including automotive, aerospace, orthopedic medical, and home electronics.

How to use the XEBEC Back Burr Cutter and Path for Tapped Hole

Men Nike Air Huarache