The global injection molding market is estimated at US$17.08 billion in 2018 and projected to reach US$19.68 billion by 2023, growing at an average of 2.9% between the period 2018 and 2023, according to Reportsnreports.com. The report further indicates that Asia Pacific injection molding machine market is expected to witness the highest expansion due to the rapidly growing automotive, packaging, consumer goods, healthcare, and electrical & electronics end-use industries in the region. While the impact of COVID-19 pandemic poses a major challenge to the industries, the injection molding machinery sector is expected to sustain its growth momentum given the important role of injection-molded plastic products in today’s lifestyle.

As the current and even future trends tend to focus on performance, reliability and sustainability, the development of highly efficient injection molding systems that meet these targets has become the ultimate goal of every machinery producer. The highly demanding requirements of various industries have pushed the injection molding machinery sector to develop powerful machines capable of large-volume production at the lowest operating costs possible. Large injection molding machines are now the popular choice of plastics manufacturers aiming for high volume, speed and reliable operations.

In this aspect, Chuan Lih Fa (CLF) has been meeting the plastics industry’s expectations with its range of injection molding machine models capable of low cost, reliable and sustainable operations. As the plastics industry takes a direction toward sustainability and smart manufacturing, CLF has gone beyond tradition to offer innovative plastics injection molding machine models with excellent structural designs to seal its leadership in the plastics industry.

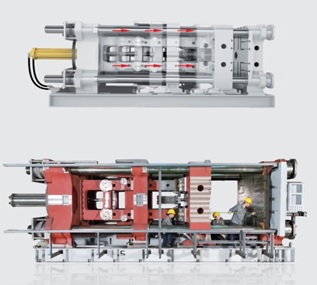

TWII Series: a breakthrough in performance

Founded in 1966, CLF has been specializing in injection molding machines that are designed to respond to the plastics industry’s ever-changing requirements. Its portfolio of injection molding machine models are creating a big difference in the various applications for which they are intended to, as the machines have been developed to overcome many barriers in the injection molding process. CLF injection molding systems boast of stable performance, strong clamping force, combination of high-tech European and Japanese microprocessor controllers, German Siemens control system and servo motors – all of which contribute to their highly efficient operations.

One such innovation is the TWII series with clamping force from 100-5000 tons. According to CLF Project Manager, Sam Lin: “The TWII Series is a large and powerful injection molding machine that has been the result of years of research and product development undertaken by CLF. The machine guarantees stable performance owing to its outward toggle type mechanism where the clamping force is concentrated at center to ensure minimum deformation of mold platen. The longer mold opening stroke allows for bigger installation space of the mold. Thanks to longer mold opening stroke, the machine model is very much suitable for deeper products.”

Mr. Lin also stressed that the TWII Series features a 5-points toggle mechanism to enable fast and smooth mold opening and closing. Since the injection unit uses linear guideway, operation leads to lower charging back pressure resistance by as much as 60%. Overall, the machine generates lower friction, fast response, smooth movement and highly precise molding operation. “TWII Series has a rigid machine structure that reduces deformation to a minimum while ensuring consistent product accuracy. This model is excellent for products requiring higher surface accuracy,” according to Mr. Lin.

TWII Series is a hard-working power-packed injection molding system for various applications that require strength, machine durability and reliability, and speed. As a leader in the industry, CLF has integrated into this model design options for flexibility and optimization. “Over the years, CLF has treated each model with the highest standards and we have poured huge investment into R&D to develop various high-precision injection molding machines that meet our customers’ requirements. The TWII Series is one example of CLF’s leadership and innovation in customizing injection molding systems for specific applications,” Mr. Lin explains.

The injection molding system TWII Series, for instance, is best for automobile production as it can produce high-precision parts such as bumpers, interiors, car lights. The model has exceeded expectations being the machine of choice in the production of electric motorbike or scooters. Leading electric scooters producer, Gogoro, relies on CLF injection molding machine to produce the scooter parts.

In addition, the TWII series is the best choice for the production of logistics products such as pallets and cases, and even housewares. “The possibilities and opportunities are abundant and the TWII Series machines are well suited to meet the needs of diverse industries. Flexibility is an added advantage in the CLF injection molding machines. For instance, TWII Series also comes in multiple injection design that can achieve multiple materials injection molding,” adds Mr. Lin.

The TWII Series has also been designed with energy-saving features such as the use of electric charging motor that enables energy savings of 30%, high-performance gearbox drive, and having the option for plasticized electric servo motor, plus an independent loop control. The clamping unit’s open/close mold speed has been increased by 15% while rigidity has risen by 30%. The system pressure has reached 170 bar.

Sustainability has been an important aspect of CLF’s commitment and apart from its energy-saving features, the TWII Series can process recycled plastic materials.

Quick response in challenging times

Over the years, CLF has rapidly expanded its markets moving forward in regions and exploring opportunities for customer base growth. To date, the company is exporting to over 40 countries around the world. As Mr. Lin explained, CLF has a strong foothold in Asia where its machines are sold and operated by customers based in China, Hong Kong, Southeast Asia, India, as well as those in Russia and the Middle East. The company has also moved forward in the European market as well as in North America and South America, while Africa is a fast-emerging market that has begun to recognize the benefits of CLF injection molding systems.

Due to increasing market demands and expansion of business, in addition to the R&D headquarters in Taiwan, CLF also operates a manufacturing plant in Zhongshan City, Guangdong Province, China, which is highly productive.

“CLF has an R&D team that closely monitors the trends and developments in our major and target markets. They focus on the smallest details to create the perfect performance in machines, and continue to bring about even higher standards of performance for future generation of injection machines that meet the needs of customers worldwide,” Mr. Lin explains. The company has been meeting the requirements of customers in diverse industries, from fulfilling production capacity, operation performance, and integrated production line planning, to after-sales services, practical and economical customization to create the best machine exclusive to the customer.

With the present coronavirus pandemic that led to various countries imposing travel restrictions, CLF has been well-prepared. Aside from its main headquarters in Taiwan, the company has offices in Vietnam and Thailand, as well as agents in Malaysia, Indonesia and other countries to provide after-sales services. “We can assist our customers remotely – so even if we don’t have an office or agent in a specific country, our technical team is always ready to assist our customers. We provide photo or video, and online assistance to help a customer install the machine, and resolve problems. Web-based meetings between our customers and technical staff are held to ensure that customers avail of immediate assistance for their non-stop operations,” Mr. Lin assures.

There is also sufficient supply of parts and components because all critical parts of CLF machines, such as mold platen, are machined in-house by Japanese-made and domestic high-precision machine tools such as Japan Toshiba floor type jig boring machines and Japan Kotobuki double column machining center.

CHUAN LIH FA MACHINERY WORKS CO.,LTD

Tel: +886-6 595 8133

Fax: +886-6 596 6168

E-mail: clf@clf.com.tw

Website: www.clf.com.tw

For more information, visit: http://www.industrysourcing.com/client/supplier/product.html?id=24111