Threads are usually made in the last stage of the manufacturing process and therefore, it is the operator’s job to make sure the process is secure and finished correctly. The thread quality and tolerance should be constant to ensure tool life is at its maximum with preferably no interruptions.

Dormer Pramet's Johan Bodin, product manager for threading, answers several questions about the company’s solid taps program, key challenges faced by machinists and the options available to end users.

Different tap designs

Johan explained there are several tap designs. The most commonly used is the straight flute. This design is suitable for blind or though-hole thread production in most materials, especially steel and cast iron. Spiral point taps are recommended for threading through holes as they feature a straight, shallow flute with a point designed to drive the swarf forward.

“Finally, spiral flute taps transport swarf back out of the hole, away from the work-piece material and therefore, are primarily used for threading blind holes. A less common but still an important part of our threading program are fluteless taps and thread milling cutters,” he added.

Different base materials in taps by Dormer

Johan revealed, “Our broad range of High Speed Steel (HSS) taps and dies support a variety of general purpose applications for use by hand or machine. All common thread forms are available in straight flute, spiral point and spiral flute designs.

“Also, our popular Shark Line program of material-specific taps is manufactured from powder metallurgy cobalt steel (HSS-E-PM). This offers optimised geometries for high performance threading in stainless steel, steel, cast iron and non-ferrous material,’ he noted.

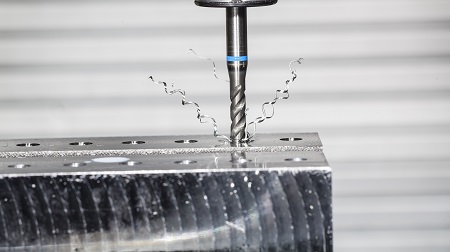

According to Johan, solid carbide taps provide the highest rates of productivity in hard and abrasive materials up to 63 HRC. Their highly stable design means low risk of tap breakage and optimum process security. Available in a variety of styles including straight flute, spiral flute and fluteless, with internal coolant options for optimum chip evacuation when threading short-chipping materials.

Forming taps

Forming taps produce a thread by deformation of the component material rather than the traditional cutting action, Johan clarified. “This means no swarf is produced and the resultant thread is stronger. Also known as roll form or fluteless, the same tap can be used to create blind and through holes in most material types, including steels up to 1200 N/mm². This makes them extremely versatile,” he added.

An important benefit of forming taps is that their highly stable design means less risk of breakage and greater dimensional accuracy, Johan said. “This is critical in applications where a reliable and dependable option is required,” he further said.

Johan stated the chamfer design determines the threading depth and type of machining. Standard forming taps with a chamfer form C, are universal for semi-bottoming below 3xD. A chamfer form E has a lead of 1.5-2mm times the pitch, which is the closest for what is called full-bottoming.

Forming taps with through coolant, radial outlets and oil grooves further support tool-life and process security. The lubricant is being delivered precisely at the point where the forces and friction is the highest, he discloses.

Milling part of taps program

Asked why thread milling is part of the company’s taps program, Johan replied the thread milling is classified within the company’s taps program. “We provide a highly accurate, larger diameter threading option on CNC machines. Dormer Pramet’s assortment covers M, MF, UNC, UNF, G & NPT thread forms.”

He added, “All provide a high level of security, stability and surface finish. Extremely versatile, the same cutter can be used in almost all workpiece materials including hardened steels, stainless steels and difficult to machine alloys.”