The global building and construction plastic market is experiencing growth owing to the increasing investment in residential and commercial infrastructure. Valued at $57.9 billion in 2017, the market is expected to reach $104.5 billion by 2025, growing by an average of 7.6% yearly, according to a report by Big Market Research.

Building and construction plastics are compounds that are ideal for products and supplies for the building and construction industry. These products are used for various purposes such as flooring, cladding & roof membranes, cables, flooring & wallcovering, insulation, piping, and window & door panels in the building and construction industry. Different types of plastic composites in flooring includes wood plastic composite (WPC), luxury vinyl tiles (LVT), and stone plastic composite (SPC). Aside from rising investment in building and construction, another important factor is seen in major players adopting various strategies such as product launches and acquisitions to stimulate the growth of the market. The rise in environmental concerns on the use of plastics are bringing technological technological advancements in the production of eco-friendly and recycled plastics for building and construction applications.

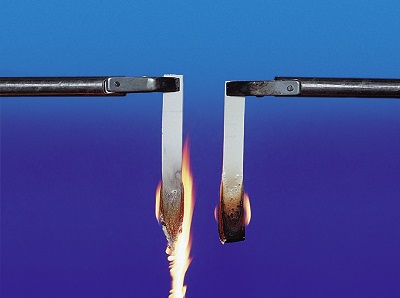

Flame-retardant additives meet high standards

Tolsa, a Madrid-based supplier of flame-retardant synergists and specialised additives for the wire and cable, construction, railway, transportation, and electronics industries, has launched an extension of its ADINS® range of flame-retardant additives for PP, PVC, rubber polymer systems, and silicones. These will be presented at K 2019.

The new ADINS® Clay synergists deliver reduced smoke production and improved heat release in PP, PVC, and rubber polymer systems, in addition to the existing FR additives used in other polymers. The company's unique FR technology continues to evolve and it sees continuing growth for clay synergists in a wide range of systems that require the highest standards of flame retardancy, according to Antonio Esteban, Technical Manager for Tolsa’s Special Additives Business Unit. As Mr. Esteban stressed, Tolsa materials are highly versatile and can be fine-tuned to meet the high-performance needs of formulators and end users.

ADINS flame retardant technology offers a versatile product range of additives for polymers that act as synergists with halogen and halogen-free flame-retardant systems. Sepiolite clay supports char creation, enhancing its mechanical properties in halogen-free systems and thanks to their structure, have very effective anti-dripping effect. Tolsa’s flexible technology facilitates modification of the sepiolite clay to meet the OEM’s strict requirements in terms of heat and smoke performance. The natural silicate clay can be modified with smoke suppressors, low-melt temperature glass, or gas-phase FR to attain good dispersion and interaction with the polymer and boost FR performance.

Tolsa’s expanded product line includes a new grade which uses titanium dioxide to improve the performance of intumescent systems for PP and coatings. This new ADINS Clay grade demonstrates further stabilisation of the char in intumescent systems (dosages of around 1-2%), improving the flame retardant efficiency. In intumescent systems, ADINS Clay decreases and delays the peak of the heat release rate and acts as a smoke suppressor. The use of ADINS Clay leads to improved cost efficiency of the formulations with intumescent flame retardants. Key end-use applications include transportation, pipe, coatings, and wire and cable.

Improvement in properties

Another company, BYK, is introducing at K 2019 its new additive BYK-MAX CT 4260, which is an organophilic sheet silicate for use in thermoplastics such as polyamides. BYK-MAX CT 4260 is the first innovative product from the new group of thermoplastic additives launched on the market under the trade name “BYK-MAX”.

It is especially suitable for use with halogen-free flame-retardant thermoplastic compounds, since incorporating the additive improves not only the flame-retardant properties but also the dropping behaviour and crust formation. In return this new, highly specialised additive also enables the filler content, e.g. aluminium or magnesium hydroxide, to be reduced. This leads to a significant improvement in the process and physical properties and to a reduction in the overall weight.

As well as improving the flame-retardant properties, the use of BYK-MAX CT 4260 can enhance barrier properties to oxygen, water vapor, and hydrocarbon. In thermoplastics, such as polyamides (PAs), and bioplastics, such as polylactides (PLAs), the melt viscosity is also increased, enabling, for example, an improvement in dimensional stability during profile extrusion to be achieved.