A digital servo controller consists of high-speed digital signal processor (DSP) to perform all calculations necessary for digital control of servo motors in torque, velocity or position mode. The controller誷 interface with control and feedback signals, such as motor currents and voltages, position encoder measurements is provided by high-resolution analog-to-digital conversion (ADC) integrated circuits. Tuning parameters that can be extracted from an auto-tuning process are stored digitally inside the hardware to eliminate manual potentiometer tuning and problems associated with analog circuit drift and aging. Furthermore, high performance DSP technology also allows for the implementation of advanced motor control algorithms such as model based predictive control for high bandwidth performance. The predictive model is derived from the state space equation of motion of laser scanner motor with motor position as observable and other dynamic variables such as current and voltage simulated. The servo predicts ahead of time the movement of laser scanner and constructs motor voltage signals to ensure that the incoming signal can be followed within the constraints of the power-supply system. The drive that incorporates state space model can deliver substantial bandwidth enhancements over an analog servo. Pulsed fiber lasers have a lot of advantages, such as excellent beam quality with the laser parameter M2 < 2[Ref1], extremely high conversion efficiency and very long life time in comparison with existing lasers such as Nd:YAG , Nd:YVO4 and CO2 lasers. It can also be operated minimal maintenance such as water-cooling and optical alignment. Materials processing has been improved very much by the usage of high repetition rate pulsed fiber lasers. The extreme short pulse width makes it easy to achieve very high peak laser intensity with low pulse energies For example, the peak power of a 20W pulsed fiber laser can reach 6KW at a repetition of 100KHz. Together with low M2 value, the laser pulse can be focused to a spot size < 100um in diameter. Because of the extremely high intensity and short laser-matter interaction times, heat diffusion is limited to the very small region and the concentration of the deposited laser energy causes rapid vaporization of the material. Hence, pulsed fiber laser can ablate high-quality and precise patterns on selected material surface in laser marking application. Since, the distance between two laser marked dots along a scan path is proportional to scanner speed and inversely proportional to pulse repetition rate, so high repetition rate pulsed fiber laser is a key element in designing a high-quality and high-speed laser marking system when the laser scanner is controlled by digital state space servo.

A digital servo controller consists of high-speed digital signal processor (DSP) to perform all calculations necessary for digital control of servo motors in torque, velocity or position mode. The controller誷 interface with control and feedback signals, such as motor currents and voltages, position encoder measurements is provided by high-resolution analog-to-digital conversion (ADC) integrated circuits. Tuning parameters that can be extracted from an auto-tuning process are stored digitally inside the hardware to eliminate manual potentiometer tuning and problems associated with analog circuit drift and aging. Furthermore, high performance DSP technology also allows for the implementation of advanced motor control algorithms such as model based predictive control for high bandwidth performance. The predictive model is derived from the state space equation of motion of laser scanner motor with motor position as observable and other dynamic variables such as current and voltage simulated. The servo predicts ahead of time the movement of laser scanner and constructs motor voltage signals to ensure that the incoming signal can be followed within the constraints of the power-supply system. The drive that incorporates state space model can deliver substantial bandwidth enhancements over an analog servo. Pulsed fiber lasers have a lot of advantages, such as excellent beam quality with the laser parameter M2 < 2[Ref1], extremely high conversion efficiency and very long life time in comparison with existing lasers such as Nd:YAG , Nd:YVO4 and CO2 lasers. It can also be operated minimal maintenance such as water-cooling and optical alignment. Materials processing has been improved very much by the usage of high repetition rate pulsed fiber lasers. The extreme short pulse width makes it easy to achieve very high peak laser intensity with low pulse energies For example, the peak power of a 20W pulsed fiber laser can reach 6KW at a repetition of 100KHz. Together with low M2 value, the laser pulse can be focused to a spot size < 100um in diameter. Because of the extremely high intensity and short laser-matter interaction times, heat diffusion is limited to the very small region and the concentration of the deposited laser energy causes rapid vaporization of the material. Hence, pulsed fiber laser can ablate high-quality and precise patterns on selected material surface in laser marking application. Since, the distance between two laser marked dots along a scan path is proportional to scanner speed and inversely proportional to pulse repetition rate, so high repetition rate pulsed fiber laser is a key element in designing a high-quality and high-speed laser marking system when the laser scanner is controlled by digital state space servo.

Experimental Results: Laser Marking Speed and Servo Bandwidth

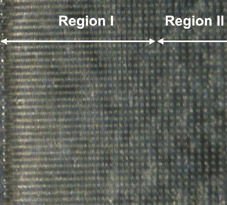

The digital laser marking system under test consists of a DC2000 digital state space servo with 6230 galvanometers with 10mm mirror set from CTI and a 20W fiber laser from SPI. The laser is running at 125KHz repetition rate. Stainless steel plates are used for the laser marking processing study. The marking performance of this system is contrasted against the output from a corresponding analog marking system driven by an optimally tuned CTI 671 anaNike Womens Shoes